Engineered wood, also known as composite wood, man-made wood, or manufactured board, is a range of derivative wood products manufactured by binding or fixing the strands, particles, fibers, or wood veneers together with adhesives or other fixation methods to form composite materials. These products are engineered to precise design specifications and tested to meet national or international standards. This makes engineered wood versatile and reliable for various applications, particularly furniture manufacturing.

Our comprehensive guide will explore the different types of engineered wood, their unique properties, and the best uses for each type in furniture production. Additionally, we’ll discuss why certain types of engineered wood are more commonly used in furniture making. Finally, we’ll introduce how Mondoro can assist you in creating, developing, and manufacturing exquisite furniture using all kinds of wood, including engineered wood.

Table of Contents

- What is Engineered Wood?

- Types of Engineered Wood

- Commonly Used Engineered Wood in Furniture Production

- How Mondoro Can Help You

- Related Content

What is Engineered Wood?

Engineered wood is created by binding wood particles, fibers, or veneers together using adhesives or other binding methods.

Unlike solid wood cut directly from logs, engineered wood combines various wood derivatives to create products that offer enhanced durability, strength, and resistance to environmental changes.

Benefits of Engineered Wood

One of the significant advantages of engineered wood is its widespread use in various types of production, including furniture manufacturing, due to several compelling reasons.

Stability:

Engineered wood is less prone to warping, shrinking, or expanding than solid wood, making it an excellent choice for furniture that needs to maintain its shape and structural integrity over time.

Cost-Effectiveness:

It is generally more affordable than solid wood, offering a cost-effective alternative without compromising quality.

Sustainability:

Using wood by-products and recycled materials in its production makes engineered wood a more environmentally friendly option.

Versatility:

Available in various forms and finishes, engineered wood can be used in a wide range of furniture styles and designs.

Types of Engineered Wood

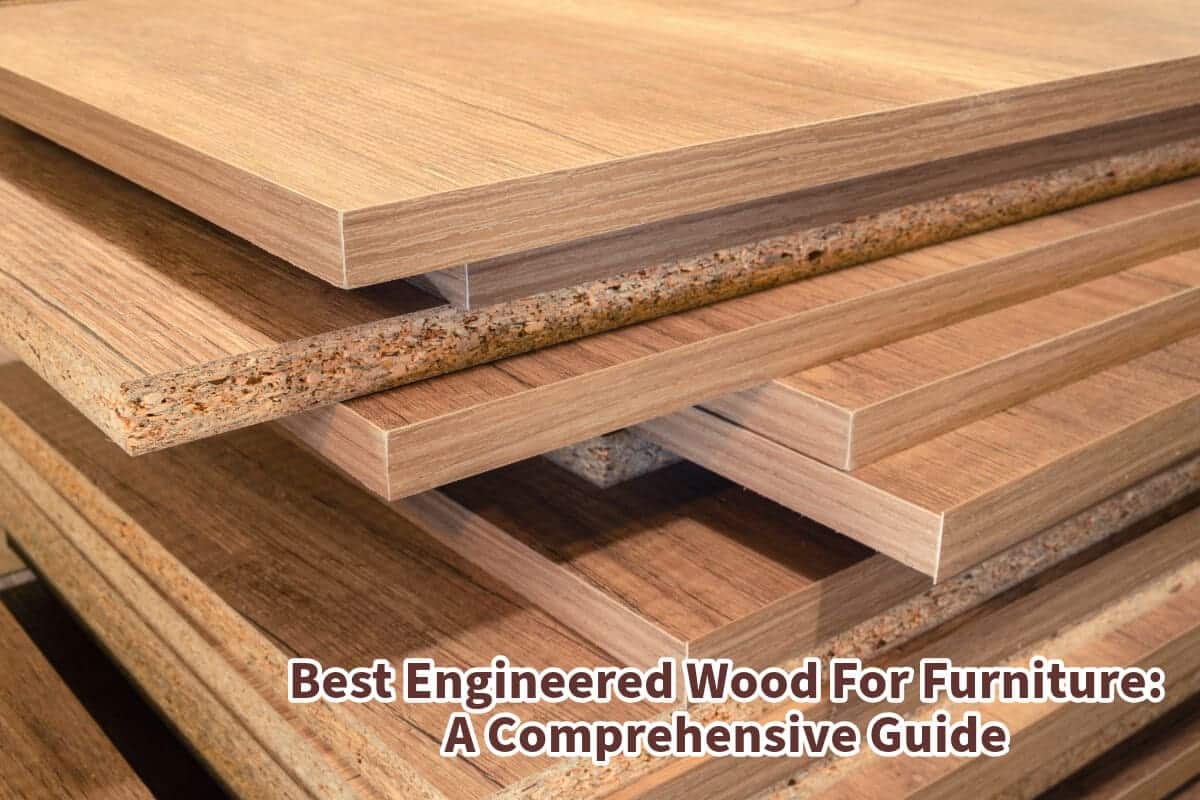

There are several types of engineered wood, each with its characteristics and best uses in furniture production. Let’s delve into the most common types:

1. Plywood

Description: Plywood is made by layering thin sheets of wood veneer, known as plies, which are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. This cross-graining technique improves the strength and stability of the material.

Best Uses: Plywood is ideal for furniture that requires strength and durability, such as:

- Cabinets: Its robust nature makes it perfect for kitchen and bathroom cabinets.

- Tables: Often used for tabletops and dining tables due to their ability to withstand heavy loads.

- Shelving: Provides sturdy and reliable shelving solutions.

2. Medium-Density Fiberboard (MDF)

Description: MDF is made from wood fibers combined with wax and a resin binder under high temperature and pressure. It is denser than plywood and has a smooth, even surface ideal for painting or veneering.

Best Uses: MDF is commonly used for furniture that requires a smooth finish, such as:

- Bookcases: Its smooth surface is perfect for painting or laminating.

- Wardrobes: Often used for the construction of wardrobe doors and panels.

- Decorative Moldings: Its ease of machining makes it ideal for intricate decorative details.

- Veneer – MDF is also great for putting Veneer on to use for a Veneer wood finish for furniture.

3. Particleboard

Description: Particleboard, or chipboard, is made from wood chips, sawmill shavings, or sawdust bonded with a synthetic resin or other suitable binder, which is pressed and extruded.

Best Uses: Particleboard is an economical choice for furniture that does not bear heavy loads, such as:

- Flat-Pack Furniture: Commonly used in affordable, ready-to-assemble furniture.

- Interior Panels: Suitable for use in interior, non-load-bearing applications.

- Desks: Often used for the construction of office desks and workstations.

4. Oriented Strand Board (OSB)

Description: OSB is made from large wood strands oriented in cross-directional layers, which are then bonded together with resins. This composition gives OSB a high strength-to-weight ratio.

Best Uses: OSB is often used in structural applications, but it can also be used in furniture, such as:

- Shelving Units: Ideal for sturdy and robust shelving solutions.

- Industrial Style Furniture: Often used in the construction of industrial-style furniture due to its rugged appearance.

- Underlayment: Provides a strong and stable base for other materials.

5. Laminated Veneer Lumber (LVL)

Description: LVL is made by layering multiple thin wood veneer sheets and bonding them with resins. This engineered wood product offers high strength and stability, making it suitable for structural applications.

Best Uses: LVL can be used in furniture that requires structural strength, such as:

- Bed Frames: Offers excellent support and durability for bed frames.

- Tables: Ideal for heavy-duty table bases.

- Structural Supports: These can be used in various furniture designs.

Commonly Used Engineered Wood in Furniture Production

Among the various types of engineered wood, some are more commonly used in furniture production due to their specific properties and cost-effectiveness. The most frequently used types include:

- Plywood is preferred for its strength, stability, and versatility. It is widely used in high-quality furniture that requires durability.

- MDF: Popular for its smooth surface, making it ideal for painted or veneered furniture. It is often used in decorative and interior furniture pieces.

- Particleboard: Chosen for its affordability and ease of use. It is commonly found in low-cost, ready-to-assemble furniture.

Manufacturers favor these materials for their quality, performance, and cost balance, making them suitable for various furniture applications.

At Mondoro, we utilize plywood and MDF for all our production processes. We are committed to ensuring superior quality engineered wood in every piece we produce.

How Mondoro Can Help You

Mondoro is dedicated to creating, developing, and manufacturing exceptional furniture using various wood materials, including engineered wood. Our expertise and commitment to quality ensure that we deliver outstanding products tailored to your specific needs.

Our Services

- Custom Design: We offer custom design services to create unique, innovative furniture pieces that meet your aesthetic and functional requirements.

- Quality Manufacturing: Our state-of-the-art manufacturing facilities and skilled craftsmen ensure that every piece of furniture is made to the highest standards.

- Material Selection: We help you choose the best materials for your furniture, considering factors such as durability, cost, and environmental impact.

- Sustainability: We are committed to sustainable practices, using eco-friendly materials and processes to minimize our environmental footprint.

Why Choose Mondoro?

- Expertise: With years of experience in the furniture industry, we have the knowledge and skills to deliver exceptional results.

- Innovation: We stay at the forefront of design and manufacturing trends, ensuring our products are stylish and functional.

- Customer Focus: We prioritize your needs and preferences, working closely with you to create furniture that perfectly suits your space and lifestyle.

- Quality Assurance: Our rigorous quality control processes ensure that every piece of furniture meets our high standards of excellence.

Engineered wood offers numerous advantages for furniture production, from its stability and cost-effectiveness to its versatility and environmental benefits. By understanding the different types of engineered wood and their best uses, you can make informed decisions about the materials you choose for your furniture projects.

With Mondoro’s expertise and commitment to quality, you can trust us to help you create beautiful, durable, and sustainable furniture that meets your exact specifications.

Listen To Our Podcast About

What Is the Best Engineered Wood for Furniture? Below or By clicking here.

If you are interested in seeing how Mondoro can be a valuable partner for you for wood furniture products – we would love to talk to you to see how we can help you.

Find out more about how Mondoro can help you create, develop, and manufacture excellent home decor and furniture products – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal. You can find it on all major podcast platforms. Try out listening to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel with great videos and information by clicking here.

Related Content

10 Types of Grain Patterns of Solid Wood Furniture Explored

We will explore ten different types of grain patterns found in solid wood furniture, including Maple, Beech, Hickory, Oak, Teak, Pine, Rubberwood, Walnut, Douglas Fir, and Spruce. We will delve into the characteristics of each wood type and examine how their distinct grain patterns contribute to their suitability for furniture production.

You can discover more by reading 10 Types of Grain Patterns of Solid Wood Furniture Explored by clicking here.

Is Solid Wood Furniture Expensive? 3 Factors To Consider

Three main factors can significantly influence the furniture price if you choose solid wood. These factors include the type of wood used, the size of the furniture piece, and the construction techniques employed, all of which play a crucial role in determining the final cost. Read on as we explore each of these.

You can learn more by reading Is Solid Wood Furniture Expensive? 3 Factors To Consider by clicking here.

Why Is It So Hard To Find Solid Wood Furniture Manufacturers?

Locating trustworthy solid wood furniture manufacturers can be an intricate endeavor for retailers and wholesalers. The task’s complexity is rooted in many factors related to solid wood furniture’s production and manufacturing procedures. Read on as we explore the complex task of the search for solid wood furniture manufacturers and how Mondoro can help you.

You can learn more by reading our blog Why Is It So Hard To Find Solid Wood Furniture Manufacturers? by clicking here.