Packing and the quality of your cartons is the central concern for product quality. If your goods are not well packed, then it can cause problems throughout the supply chain.

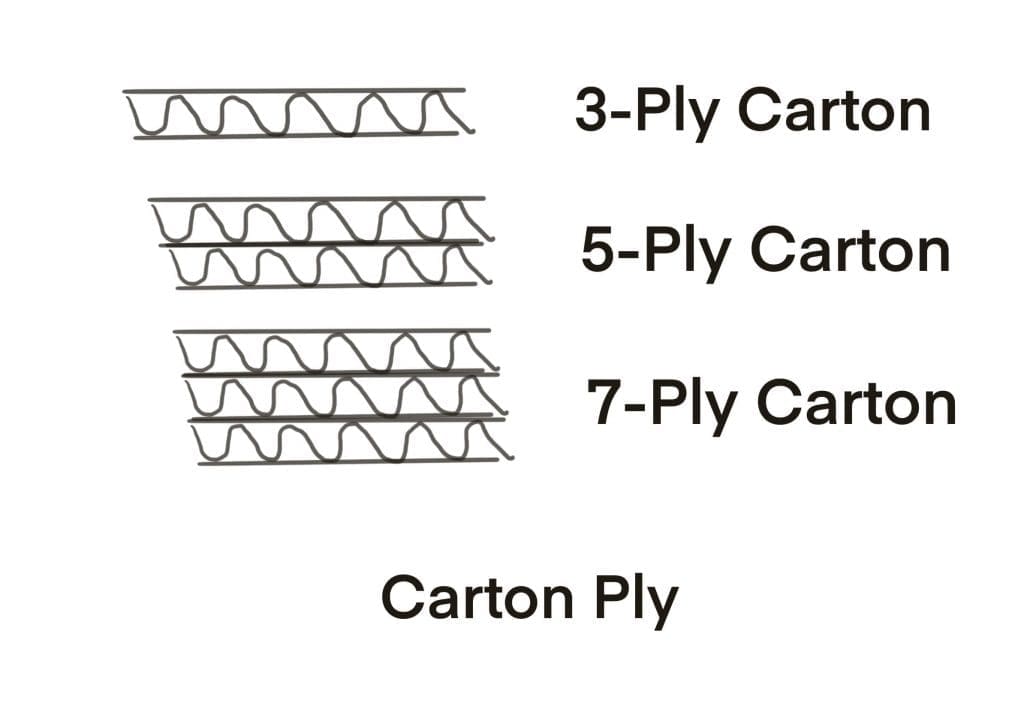

Knowing the different ply values in corrugated cartons is essential to understanding packing carton quality. Corrugated cartons are constructed with kraft or test paper made into cartons using flute construction. The most common corrugated cartons are 3-ply, 5-ply, and 7-ply corrugated cartons.

Table of Contents

- All About Corrugated Paper Used in Cartons

- The Ply Value In Corrugated Carton Boxes Explained

- Frequently Asked Questions

- Related Content

All About Corrugated Paper Used in Cartons

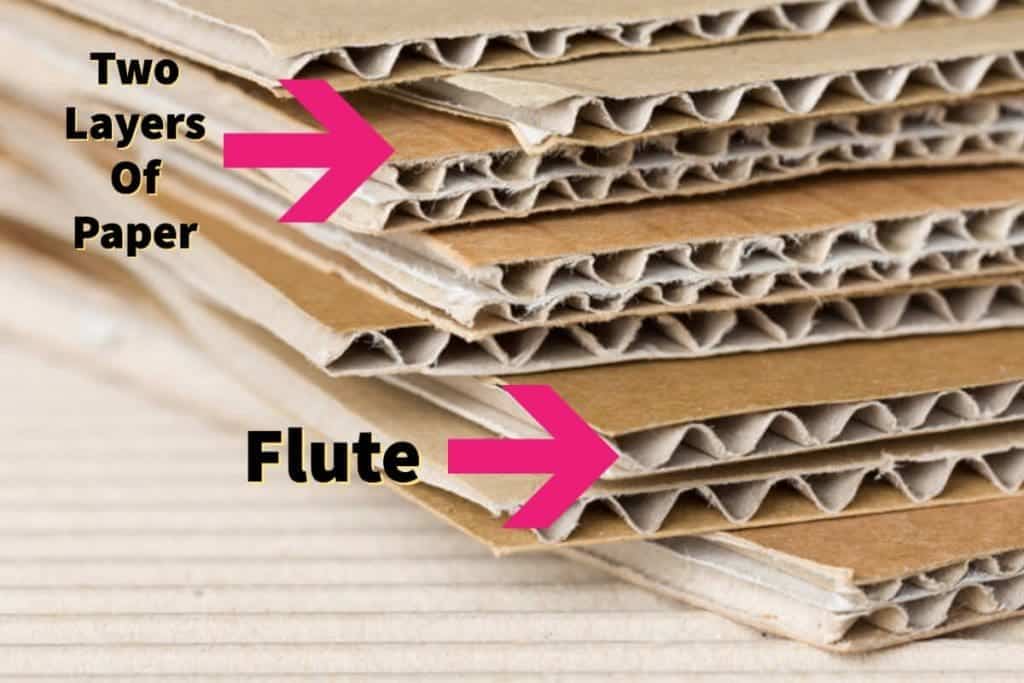

Corrugated cardboard is made up of three different components. The three components are shown below:

For corrugated cardboard, you have a fluted material in the center, placed between two layers of paper. The center corrugated piece makes this a “corrugated cardboard box.”

Like most things, the quality of the carton depends on many factors. One of the key factors for the quality of the carton is the type of paper used.

The type of paper used depends on many things, and one is simply what kind and quality of paper are available locally where the cardboard is being manufactured. Another is if the cardboard supplier has all the necessary technological expertise.

Two common types of paper are used in corrugated cartons, i.e., kraft and test paper; here is what each of these means:

- Kraft Paper – Kraft paper is usually manufactured from softwood trees. This means that the paper is considered to be “virgin” paper. Kraft paper is the strongest type of paper and also the easiest type to print on. As a result, most corrugated cardboard suppliers will use Kraft paper on the outside side of the corrugated carton. In addition, most manufacturers need to print a shipping mark on the outside of the carton.

- Test Paper – Test paper is recycled paper. It is a double-layered paper. It is not as strong as kraft paper or as easy to print on, so it is commonly used for the inner liner of a carton.

Like most kinds of paper, the quality of the paper can vary greatly according to the technology and how the paper manufacturer can make the paper. The quality of the paper also depends on the actual paperweight.

When we talk about weights for the paper, we normally talk about GSM. GSM is an abbreviation of grams per square meter. So this means that if you took a square meter of paper and weigh it, this would be the weight or grams per square meter of that paper.

Another important part of any corrugated cardboard is the flute. This is because the sizes of flute can vary as much as the cardboard. The size of the flute is counted as how many loops there are per linear foot. A double wall carton, for example, would have two rows of flutes

If this is seeming all a bit technical – it actually is. So many variables can distinguish which corrugated carton box is of the quality needed to protect the products.

The Ply Value In Corrugated Carton Boxes Explained

Now that we understand a little bit about the flutes and how a corrugated cardboard box is constructed, we can talk about the difference between what each cardboard ply values.

Below are some of the major differences between the different ply values of corrugated cartons that are being used:

3-Ply Corrugated Carton

A 3-ply corrugated carton has one flute between 2 line boards. This three-ply corrugated carton is usually used as an inner carton or for lightweight products. In other words, it is suitable for shipping and storing products that are not heavy or using them as an inner carton that will be placed inside of a more robust outer carton.

We will not use a 3-ply carton as the outer carton for most of the products that we produce,

as it is not strong enough. Still, we will only use a 3-ply corrugated carton as an inner carton—a normal 3-ply corrugated carton that handles about 4 to 15 kilos or 8 to 33 pounds.

5-Ply Corrugated Carton

A 5-ply corrugated carton will have two sections of fluted paper sandwiched between 3 linear boards. A 5-ply carton can usually handle pressure and be stacked up for transportation.

This is one of the most common cartons used to export goods. The 5-ply corrugated cartons are economical and strong and can handle a lot of weight and handling.

A 5-ply carton that is made well can handle a lot of weight and handling.

7-Ply Corrugated Carton

A 7-ply corrugated carton would have 3 layers of flutes between 4 linear boards This carton has one extra row of flutes and linear boards from a 5-ply carton.

7-ply cartons should be used to pack items such as very heavy furniture, metal parts, or items that require a very strong carton.

When considering which kind of corrugated carton to use for your products or shipment of goods, you should conduct a product drop test. To learn more about how to conduct a drop test on your products, you can read our blog What is a Product Packaging Drop-test? by clicking here.

At Mondoro, we understand that the correct packaging is essential to our customers. That is why we always strive to have the best quality carton we can find. We also regularly conduct product drop tests.

Listen To Our Podcast About The Carton Chronicles:

Navigating Ply Values in Corrugated Packaging

Below or By clicking here.

Find out more about how Mondoro can help you create, develop, and manufacture excellent home decor and furniture products – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal. You can find it on all major podcast platforms. Try out listening to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel filled with great videos and information by clicking here.

Frequently Asked Questions

1. What is the ply value in corrugated carton boxes?

The ply value in corrugated carton boxes refers to the number of layers or sheets of paper that make up the carton’s construction. It is a critical factor in determining the carton’s strength and durability.

2. How is the ply value of corrugated cartons determined?

The ply value is determined by the number of layers or sheets of paper used in the construction of the carton. For example, a 3-ply carton has three layers of paper, while a 5-ply carton has five layers.

3. What are the most common ply values for corrugated carton boxes?

The most common ply values for corrugated carton boxes are 3-ply, 5-ply, and 7-ply. These values indicate the number of layers used in the carton’s construction.

4. How does the ply value affect the strength of corrugated carton boxes?

The ply value directly impacts the strength of corrugated carton boxes. Higher ply values generally result in stronger and more durable cartons, capable of withstanding heavier loads and providing better protection to the packaged goods.

5. What are the advantages of using higher ply value corrugated carton boxes?

Higher ply value carton boxes offer increased strength and durability, making them suitable for heavier or fragile items. They provide better stacking capability and protection during shipping and storage.

6. In what situations are lower ply value corrugated carton boxes appropriate?

Lower ply value corrugated carton boxes are suitable for lighter items or products that do not require as much protection during transit. They are often more cost-effective for such applications.

7. How can I determine the appropriate ply value for my packaging needs?

To determine the right ply value, consider the weight and fragility of your products, as well as the anticipated stresses during shipping and handling. Consult with packaging experts or suppliers for recommendations.

8. Are there other factors besides ply value that affect carton box quality?

Yes, carton box quality is also influenced by factors such as the type of paper used, flute size, and the construction method. Ply value is just one aspect of overall carton quality.

9. Can corrugated carton boxes with higher ply values be recycled?

Yes, corrugated carton boxes with higher ply values can still be recycled. Recycling processes can handle various ply values, but it’s essential to follow local recycling guidelines.

10. How does the quality of corrugated carton boxes impact product quality and the supply chain?

The quality of corrugated carton boxes directly affects product quality and the efficiency of the supply chain. Poor-quality cartons can lead to damaged goods, increased shipping costs, and delays in delivery, ultimately impacting customer satisfaction and profitability. Choosing the right ply value and carton quality is crucial for a smooth supply chain operation.

Related Content

What is the Pre-shipment Inspection or PSI?

A Pre-shipment Inspection (PSI) is an inspection that takes place once the goods are completed and ready to be shipped. The Pre-shipment Inspection helps ensure that the manufactured products are of the quality, quantity, and price ordered.

You can find out more about the pre-shipment inspection by reading our blog The Pre-shipment Inspection Guide and Product Quality Assurance by clicking here.

What is the DUPRO or During the Production Product Inspection?

The DUPRO Inspection is a product inspection conducted during the manufacturing phase of production. The DUPRO is also known during the production inspection. Its main purpose is to find any errors during the product’s manufacturing phase. Most manufacturing errors are easier to fix during the production process than when goods are completed.

You can find out more by reading our blog DUPRO, During the Production Product Inspection Guide by clicking here.