We use glass a lot in our home decor and home furnishing production, especially as part of products such as glass tabletops.

Glass is generally made by heating sand or a sand mixture up to a very high temperature so the sand melts. Once the sand mixture is liquid, it can be poured and rolled into a flat glass, pressed into a shape, or blown into a piece of art glass. Once the glass mixture cools, the glass is formed. Tempered glass is a solid glass used for many products due to its strength and how the glass will not break into many pieces. Tempered glass is produced similarly to regular glass, except it goes through some extra steps to add compression strength to the glass.

Table of Contents

- Formula And Chemistry Of Glass

- All About Tempered Glass

- 10 Reasons Mondoro Chooses Tempered Glass for Home Decor and Furniture

- Frequently Asked Question

- Related Content

Formula And Chemistry Of Glass

Glass has traditionally been made by melting sand. The main ingredient of glass is SiO2, which is also known as silica sand. Silica sand has a very high melting temperature of about 1700 degrees C (3092 degrees F); when it is melted, the silica sand becomes like a syrup-type texture.

The sand can have additives such as soda ash and limestone before being heated at a very high temperature of 1700 degrees C. Once the substance is melted, it can be formed into various objects like glass bottles, containers, and flat glass that can be used as a tabletop.

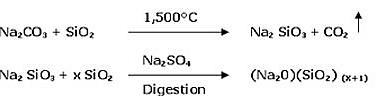

The chemical formula of glass is listed as:

Chemical Formula of Glass

Manufacturing Of Glass Explained

In simple terms, glass is made from sand that is melted at very high temperatures so that the glass will melt and become a liquid form. Once the sand becomes a liquid, then it can be shaped.

The hot liquid will be poured into a machine that rolls the glass into a flat piece to produce flat glass panels. The thickness of the glass will depend on how the device is set up to allow what kind of thickness.

If the glass is needed for a bottle, bowl, or another shape, then the glass can be put into a mold and pressed into shape. The glass can also alternatively be blown into a specific shape.

As the heated glass mixture starts to cool, it becomes solid and glass.

The basic process of glass is as follows:

- Sand or Sand mixture is heated at very high temperatures in a kiln oven that can reach 1700 degrees C or up to 3,000 degrees F.

- The sand mixture melts.

- The sand mixture is poured, pressed, or blown into the glass shape.

- When the sand mixture cools, the glass is formed.

All About Tempered Glass

The glass we use for our table tops is a glass known as tempered glass. Tempered glass is preferred for many home decor and home furnishing items as the glass is about four times stronger than regular glass.

If the tempered glass breaks, it will break into relatively harmless small pieces or cracks. That is also why temperated glass is used for windows in vehicles, doors, showers, microwave ovens, skylights, and furniture.

Here is the basic process of making tempered glass:

- Glass is cut into its desired shape. Things like edging and etching need to take place before the glass is tempered, as doing it after can reduce the strength of the glass.

- Glass is examined to ensure no imperfections can cause breakage for the tempered glass. Some imperfections that are looked for include bubbles, stones, scratches, or other significant flaws that can potentially weaken the glass.

- Glass is placed in a heat treatment process of about 620 Degrees Celsius or 1,148 Degrees Fahrenheit.

- Glass then undergoes a high-pressure cooling procedure known as “quenching.” The quenching process lasts just a few seconds as a high-pressure air blasts the surface of the glass.

If the high-pressure quenching process is not used, there is also a chemical tempering that uses various kinds of chemicals on the surface of the glass to cause compression. The chemical process usually costs more than the tempering ovens and quenching, so it is not used frequently.

One of the essential things with tempered glass is that the glass is compressed. The compression when the high-pressured quenching or chemical tempering is conducted makes the glass tempered glass.

During the compression process, the glass’s outer part cools much faster than the center. It is the process of tension that causes compression and gives the tempered glass its added strength.

The Federal Glass standard states that tempered glass must have a surface compression of 10,000 psi or more. Tempered glass will generally break at 24,000 psi.

Glass is a material used extensively in home decor and home furnishing products. Glass, especially tempered glass, can protect the surface of a table or other piece of furniture while giving some added beauty.

10 Reasons Mondoro Chooses Tempered Glass for Home Decor and Furniture

At Mondoro, our commitment goes beyond just aesthetics; we prioritize safety and durability in all our creations. Despite the higher costs, our unwavering preference for tempered glass in our home decor and furniture products stems from a multitude of reasons. Here’s why we champion the use of tempered glass:

- Enhanced Safety: The foremost reason is safety. If broken, tempered glass crumbles into small, rounded chunks rather than jagged shards, significantly reducing the risk of injury.

- Superior Strength: Tempered glass undergoes a heat treatment process that makes it up to five times stronger than regular glass, ensuring longevity and resistance to breakage.

- Thermal Resistance: The tempering process enhances the glass’s ability to withstand temperature changes, making it less likely to break under rapid temperature fluctuations.

- Clear Aesthetics: While maintaining its strength, tempered glass retains its clear, pristine appearance, making it ideal for chic and modern home decor and furniture designs.

- Cost-effective in the Long Run: Though initially more expensive than regular glass, the durability and reduced need for replacements make tempered glass more cost-effective over time.

- Protection Against UV Rays: Some tempered glasses offer UV protection, shielding interiors and preventing the fading of fabrics and furnishings due to sunlight.

- Customization: Despite its strength, tempered glass can be crafted into a plethora of designs, shapes, and finishes, ensuring that design integrity is never compromised.

- Easy Maintenance: Resistant to scratches and tough against wear and tear, tempered glass requires minimal maintenance, making it a practical choice for homes and commercial spaces.

- Enhanced Value: The use of tempered glass, with its blend of safety and aesthetics, can elevate the value of a piece, making it a sought-after feature for discerning customers.

- Ethical Responsibility: At Mondoro, our ethos revolves around delivering beautiful and safe products for our customers. By using tempered glass, we uphold our commitment to responsible craftsmanship.

While tempered glass might come with a heftier price tag initially, its manifold benefits, especially in safety and durability, align perfectly with Mondoro’s vision of creating home decor and furniture products that stand the test of time and safeguard the well-being of our customers. We believe that in melding quality with safety, we craft not just products but trust.

If you are interested in seeing how Mondoro can be a valuable partner for your glass home decor and home furnishing products – we would love to talk to you to see how we can help you.

Find out more about how Mondoro can help you create, develop, and manufacture excellent home decor and home furniture products – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal. You can find it on all major podcast platforms. Try out to listen to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel filled with great videos and information by clicking here.

Frequently Asked Question

What is the formula of glass?

The formula of glass is typically represented as SiO2, which means it consists primarily of silicon dioxide.

How is glass made?

Glass is generally made by heating sand or a sand mixture to a high temperature until it melts. The molten mixture can then be shaped, cooled, and solidified to form glass.

What is the main component of glass?

Silicon dioxide (SiO2) is the main component of glass. It is commonly found in sand and is the primary ingredient used in glass production.

Can glass be made without sand?

While sand is the most common source of silicon dioxide used in glass production, other materials rich in silica, such as quartz, can be used as substitutes

How is glass shaped?

Once the glass mixture is in a molten state, it can be poured and rolled into flat sheets, pressed into specific shapes using molds, or blown into various forms by skilled artisans.

What is the temperature required to melt sand and make glass?

The temperature required to melt sand and form glass typically ranges from approximately 1700 to 2200 degrees Celsius (3092 to 3992 degrees Fahrenheit).

How does glass solidify?

When the molten glass cools down, it undergoes a process called solidification, where it transitions from a liquid state to a solid state. As it cools, the molecules arrange themselves into an amorphous, solid structure.

Can glass be recycled?

Yes, glass is highly recyclable. It can be melted down and reused to create new glass products repeatedly without losing its quality.

Related Content

What Is The Difference Between LED, CFL, and Incandescent Light Bulbs?

They can be a little bit of confusion about what the difference is between an LED or incandescent bulb and which light bulb is really the most energy-efficient one to use.

You can discover more by reading What Is The Difference Between LED, CFL, and Incandescent Light Bulbs? by clicking here.

What are the Standard Light Bulb Base Socket Types and Sizes?

Considering different types of light bulb socket bases can get quite confusing. Many people get confused about the different numbers used for each light bulb base and their meanings.

You can discover more by reading our blog What are the Standard Light Bulb Base Socket Types and Sizes? by clicking here.

Do Your Lighting Products Need To Be UL Or ETL Listed?

Products sold or imported into the United States or Canada should have a UL or ETL mark to show they are UL or ETL listed. UL and ETL-listed products show that they have passed particular safety and other standards and have verified “third-party certification.” For buildings, the building code inspectors will ensure that all electrical products, including the lighting, have UL or ETL marks and certifications sold in a commercial buildings.

You can discover more by reading our blog Do Your Lighting Products Need To Be UL Or ETL Listed? by clicking here.