Gold leafing or gilding is an ancient art form that has been used for many centuries. It is also an art form that is relevant to our development and manufacturing of home decor and home furniture products in our day and time.

The gold leaf is hammered gold. Some gold leaf manufactured today is actually hammered, copper or gold mixed with other metals and alloys. The gold leaf is manufactured by gold beating. The process of gold beating is to beat or press the gold into fragile sheets of paper.

This gold beating technique was discovered over 5,000 years ago. Today there are many wonderful uses for the gold leaf finish for home decor and home furniture product development.

What is Gold Leaf?

Gold leaf is gold that is hammered into very thin sheets by what is known as gold beating. Gold leaf is often used for gilding. Gilding is the process of putting the thin coat of gold leaf on a decorative object such as metal, wood, MDF, porcelain or stone.

The Oxford Dictionary defines gold leaf as:

“Gold that has been beaten into a very thin sheet, used in gilding.”

Oxford dictionary

What is Gold Beating?

Gold beating is the process of hammering the gold into extremely thin sheets for use in gilding. Those that do the hammering are usually called gold beaters.

Here is the basic information about gold leaf and gold beating

- The karat and color of the gold leaf sheets depend on the amount of silver and copper that is added to the gold leaf.

- The gold and its alloys are put into a big crucible and then melted in a furnace before being put into gold bars.

- The gold bars are then beat, pounded, pressed and stretched into very thin sheets which are about 1.1.2/ 7,000 millimeters thick.

- Today the gold leaf is not actually beat as much as pressed and rolled out of a machine. Gold leaf is pressed and rolled many times to get to the thickness required.

- This process is done by machine in part due to the fragile nature of handling the gold leaf.

- These thin sheets of gold are so thin that if you touch it with your hands they will easily crumble.

- The gold leaf sheets cannot be layered on top of each other or they will stick together, so they are each placed into small thin sheets of paper.

- A lot of the gold leaf today does not use solid gold or a gold alloy, instead, it will be made from brass with a combination of copper and zinc.

- This so-called imitation gold leaf can also be referred to as Composition gold leaf, Dutch Metal. Dutch Gold and Schlagmetal.

- The color of the gold leaf comes from what material is mixed in it. Gold leaf mixed with copper is called red gold, while gold leaf mixed with silver is called white gold.

History of Gold Leaf

It is interesting to know a bit about the history of this ancient art form of gold leaf and gilding that is still being used today.

Here is some historical context for this very important art form of gold leaf:

- Over 5,000 years ago the Egyptian artisans discovered that gold was extremely durable and yet malleability.

- The Egyptians started to become the first goldbeater’s and gilders.

- The Egyptians would pound the gold using a round stone to create the thinnest layer of gold as possible. Some of their gold was pounded down to 24 micrometers or 1/100 inch.

- During the European Bronze Age, the gold leaf would be used to decorate many kinds of objects, especially religious objects.

- Early 20th Century leather books had gold leafing on them for ornamentation.

- Buddhist art also used a lot of gold leaf to decorate statues and symbols. If you have ever been to Thailand you can see many of the ancient temples have gold leaf on their wood carvings.

- Gold leaf was used a lot in architecture. Buildings like the Basilica di Santa Maria Maggiore in Rome used gold mosaics and gold leaf walls.

- The Palace of Versailles in France also used a lot of gold leaf decoration.

Gold Leaf and Vietnamese Lacquer

Vietnamese have been working with gold leafing and lacquer for centuries. The Vietnamese will use the gold leaf as part of their lacquer artform. Many older Vietnamese objects and antiques use a lot of gold leaf finishes on them.

To find out more about Vietnam lacquer you can read our blog entitled How to Manufacture Vietnamese Lacquerware? by clicking here. This blog gives you many insights into the Vietnamese lacquerware including its history and how it is produced.

How To Use Gold Leaf For Home Decor and Home Furniture Products?

There are many ways you can use the gold leaf finish on Home Decor and home furniture products. This ancient technique can be used on almost any kind of product.

Here are some ideas and ways to develop gold leaf on home decor and home furniture products.

Furniture – Gold leaf can be used on part or all of a furniture product. We have even used it inside of cabinet, drawers and or as trimming as part of another finish. It can also be used as a base coat for other finishes. So many times gold leaf is being used for a finish but as there is finish on top of it you may not realize that gold leaf is the base coat.

Lamps and Lighting – You can use gold leaf as part of your lamp base or for the entire lamp base or light. It can also be put on an MDF base, ceramic or resin. It just depends on the shape and size of the base.

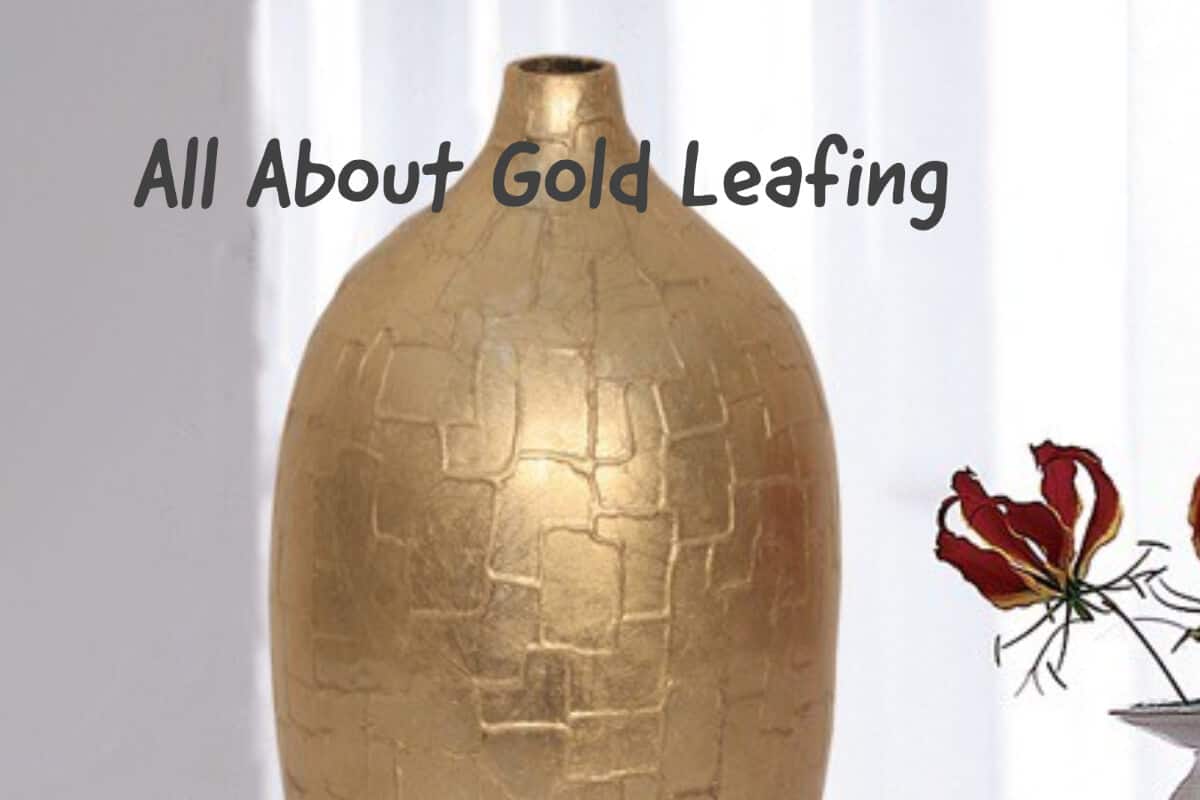

Home Decor Accessories – One of the most popular ways that gold leaf is used is on home decor accessories. This would include things as trays, boxes, vases and bathroom accessories.

Wall Art & Mirrors – The gold leaf is used a lot on wall art and mirrors. We can use it for part of the product or for the entire piece. Also with a topcoat or finish we can make it so that it has a gradient finish so there can be several tones of the same color but all with a gold leaf base coat.

Using gold leaf is an ancient technique that is rich in history. It is an artistic technique that is still relevant today for home decor and home accessories product development.

Related Questions

What is the Mother of Pearl Shell Used in Home Decor Products?

Today many home decor and home furnishing products are produced using the natural material of mother of pearl. The production of the mother of pearl products has a long and rich history in many places including in Vietnam.

Mother of pearl, which is also known by the scientific name of nacre, is a pearl layer on the inner layer of the oyster shell. This pearl layer of the oyster is taken off the outer oyster shell. Then the leftover inner pearl shell is cut into various small shapes and sizes to then be glued on to various home decor products as mirrors, boxes, trays and lamp bases.

You can read our blog entitled What is the Mother of Pearl Shell Used in Home Decor Products? by clicking here.

What are Vietnam’s French Encaustic Cement Tiles?

The French encaustic cement tile is a cement tile that has a design in clay on the top surface of the tile. The design is pressed into a layer so the cement tiles have two layers, one with the pattern and one bottom layer. The tiles have been manufactured and made throughout the world. The French brought the encaustic cement tiles production to Vietnam in the 1850s. Since that time, the Vietnamese have continued to manufacture these encaustic cement tiles, using many of the old French designs along with some of their modern designs. The Vietnamese manufacturers export the encaustic cement tiles around the world and use them presently in many buildings in present-day Vietnam.

You can read our blog called Vietnam’s French Encaustic Cement Tiles, What You Need to Know by clicking here.