Many Vietnamese households in the lacquer villages outside Hanoi have produced lacquer for 600 years. Mondoro has worked for many years in these villages to help them develop and keep their artistic handicraft skills, culture, and traditions alive.

Vietnamese lacquer requires many manufacturing steps in the lacquer production process, including making the base, preparing the lacquer base to be applied, and finally applying the lacquer paint onto the surface. Every piece must be carefully sanded to give it a very smooth surface. Vietnamese lacquerware production requires a lot of skill and knowledge.

Table of Contents

- Does Producing Vietnamese Lacquerware Require A Lot Of Skill?

- Is Vietnamese Lacquerware Durable?

- Frequently Asked Questions

- Related Content

There are many ways that Mondoro is actively working to help the lacquer community in Vietnam. We believe that this is a local handicraft skill set that should thrive and be kept alive. But with many handicrafts, we also need to update the lacquer look and finish to fit today’s home decor and furniture trends.

Does Producing Vietnamese Lacquerware Require A Lot Of Skill?

Vietnamese lacquer production requires a lot of technical skills and knowledge. Most of the people who produce lacquer have grown up in one of Vietnam’s lacquer villages, so it can be said that they have essentially grown up on the factory floor. The family may live in a home in the front of their factory, while the lacquer manufacturing is in the back of their home.

These lacquer-producing families have been manufacturing lacquer for hundreds of years in these handicraft villages. The craft of lacquer production has been passed down from father to son and now, in many cases – from mother to daughter.

This has helped keep the lacquer production handicraft skill alive within the villages. It also means that the skill level of the artisans is extremely high. These artisans all understand all aspects of lacquer production as they have certainly earned the title of “lacquer expert.”

What Base Surfaces Can You Use For Lacquerware Production?

To produce lacquer, you must first prepare the base on which you want to apply the lacquer. Lacquer can be applied to ceramic, resin, wood, fiberglass, spun bamboo, plywood, medium-density fiberboard (MDF), plastic, and coconut shell bases. Most surfaces and shapes can be used to apply the lacquer technique.

Lacquer is a versatile material, as it works well on many kinds and types of surfaces. We have even mixed various base materials or surfaces in our production process. Since the lacquer preparation is the same for all the materials, the result is that the paint on a variety of surfaces looks similar.

How Do You Prepare The Vietnamese Lacquerware Bases?

Lacquer bases are prepared by applying multiple lacquers of thin black mud to the surface, letting the mud dry, and sanding the surface between layers. This process is repeated many times throughout the entire production process.

It is both a labor- and skill-intensive process, requiring a lot of hand labor as many parts are so sensitive that you cannot use sanding machines as the surface must be sanded by hand. Yet it is also skill-sensitive as the production of lacquer requires the required technical knowledge and skillset to understand when the base is dry enough to be sanded.

Though sanding and applying the mud is at the beginning stages of the lacquer manufacturing process, it is also one of the most important stages. If this mud is not mixed correctly, applied properly, or appropriately sanded, it can affect the overall quality of the product.

Lacquer production is a built-up kind of production. This means that we start with a base, and then with the clay, we add or build up the surface of the base bit by bit or little by little. It also takes time, as it cannot be done all at once, but it must be done carefully with a thin coat upon a thin coat of mud layered on the surface. Each step must be checked, dried, and then sanded carefully.

Vietnamese lacquer production applies the clay mud, drying the mud, and finally sanding off the mud. All of this is repeated until the surface is entirely and perfectly smooth.

When we work with some large-scale items, such as some furniture pieces, we will add the additional step of wrapping the entire large furniture piece in a light gauze fabric. This will help to add strength and stability to the overall piece.

What Finishes Can You Put on Vietnamese Lacquerware Pieces?

There are many types of finishes that you can put on a lacquer piece, such as you can paint the piece one color and having a very smooth, clean surface. Or you can build up the surface to give it some dimension and texture.

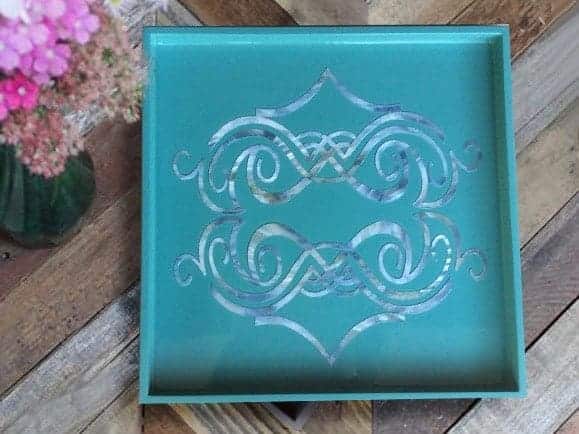

We can also apply gold and silver leaves to our production. We often use the gold and silver leaf as a base coat, then build upon it and sand down to the gold and silver leaf layer. Lacquer production also uses a lot of Mother of Pearl and eggshells.

The beauty of the Vietnamese lacquer is its lasting finish and color possibilities. We can use the lacquer technique and materials to create new and exciting finishes so many different ways.

The skillset is all there as the Vietnamese have produced lacquer for so many years. At Mondoro, we work with these small but highly skilled artisan producers to help direct them by introducing trend-worthy colors and finishes.

Is Vietnamese Lacquerware Durable?

Because Vietnamese lacquer production is so intricate, many think it must be fragile. But the truth is when Vietnamese lacquer is manufactured correctly, it is highly durable. We have found Vietnamese lacquer to withstand various harsh weather and climate changes.

To ensure your lacquer will last long, you must use a qualified manufacturer that does not cheat or cut down on the various lacquer production steps. At Mondoro, we are very strict about this and only work with those suppliers we know will not cheat or cut out any of the lacquer production steps or processes.

The production of Vietnamese lacquer is not only an ancient handicraft but it is also a complex skill that requires a lot of expertise and training. It is also an art form passed down for many generations. Therefore, when you purchase a lacquer piece, you help keep this critical art form alive.

Frequently Asked Questions

Why are traditional handicrafts like Vietnamese lacquerware so important?

Handicrafts like Vietnamese lacquerware are essential to a nation’s artistic and cultural identity. For Vietnam, lacquerware is not only a critical handicraft; it is a source of pride for the Vietnamese people. In the case of Vietnamese lacquerware, knowledge, and manufacturing expertise are necessary to pass down from generation to generation.

Where can I buy Vietnamese lacquer?

If you visit Vietnam, you can find many lacquerware items anywhere they are selling handicrafts or tourist items. Some art galleries in Vietnam sell some lacquer paintings that Vietnamese artists painted.

If you are looking for lacquerware to import, you can contact Mondoro by clicking here. We would be happy to show you our lacquerware production and samples, plus many color chips and finishes. Our finish library has thousands of unique color chips and finishes.

What is Vietnamese lacquerware?

Vietnamese lacquerware is a traditional craft involving the use of lacquer to create beautifully decorated items, ranging from small trinkets to large furniture. It is known for its intricate designs and vibrant, glossy finish.

How is Vietnamese lacquerware made?

The process involves applying several layers of lacquer, often derived from tree resin, onto a base material like wood or bamboo. Between each layer, the item is sanded and polished. Decorative elements like eggshell, mother-of-pearl, or gold leaf are often inlaid into the lacquer.

What makes Vietnamese lacquerware unique?

Its uniqueness lies in the detailed craftsmanship and the use of natural materials for inlay work, which often reflect Vietnamese culture and landscapes. The meticulous layering process also gives it a distinctive depth and richness.

How long does it take to create a piece of lacquerware?

The creation of a single piece can take several weeks to months, depending on the complexity of the design and the number of lacquer layers applied.

How do I care for and maintain Vietnamese lacquerware?

To maintain its shine and prevent cracking, keep lacquerware out of direct sunlight and avoid exposure to extreme temperatures. Clean gently with a soft, dry cloth.

How can I tell if a piece of lacquerware is authentic?

Authentic lacquerware usually has a high level of craftsmanship, depth of color, and intricacy in design. It’s best to buy from reputable artisans or stores.

Is Vietnamese lacquerware environmentally friendly?

Traditional lacquerware uses natural lacquer and materials, making it relatively eco-friendly. However, modern variations might include synthetic materials.

Find out more about how Mondoro can help you create, develop, and manufacture excellent home decor and furniture products – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal. You can find it on all major podcast platforms. Try out listening to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel with great videos and information by clicking here.

Related Content

Acrylic Lacquer Paints: Finish For Various Products

Their application spans a broad spectrum, from the sleek bodies of classic cars to the vibrant curves of guitars and onto the cherished surfaces of antique furniture. Acrylic lacquer’s popularity is no coincidence—it’s a testament to its superior qualities and the finish it delivers. Read on as we explore the essence of acrylic lacquer, examining its distinct characteristics and the reasons behind its widespread adoption across diverse finishing practices.

You can discover more by reading Acrylic Lacquer Paints: Finish For Various Products by clicking here.

Latex Paint Vs. Acrylic Paint: 20 Key Differences

Two types stand out as the most recognized when exploring the world of paints: latex and acrylic paint. While these paints might appear similar at first glance, they possess distinct differences. Join us as we delve into the definitions of each paint and highlight their unique characteristics.

By clicking here, you can learn more by reading Latex Paint Vs. Acrylic Paint: 20 Key Differences.

Differences Between Lacquer, Acrylic, and Enamel Paint

Lacquer paint is a quick-drying paint that is very hard and scratch-resistant; it is a traditional paint used for handicraft production in Vietnam and Japan. Acrylic paint is one of the most versatile paints and easiest to work with; acrylic paint can be used with water. Enamel paint is also a paint that dries hard but usually has a shiny topcoat.

You can learn more by reading our blog Differences Between Lacquer, Acrylic, and Enamel Paint by clicking here.