In our rapidly evolving world, the tapestry of global commerce grows ever more complex. Supply chains extend across continents, stitching together economies and markets into a unified yet challenging global marketplace. The globalization of supply chains has created a labyrinthine network of cross-border trade agreements, international logistics, and technological interconnectivity, presenting unprecedented opportunities for businesses to source materials and goods from every corner of the globe.

As this intricate system functions as the backbone of international trade, understanding its nuances is crucial for any contemporary enterprise aiming to thrive within this dynamic environment. This exploration will shed light on the complexities and innovations driving these expansive networks and the potential pitfalls organizations must navigate to maintain competitiveness and resilience in a world without borders.

Table of Contents

- Globalization of Supply Chains

- Risk Management in Global Supply Chains

- Technology’s Role in Supply Chain Management

- Sustainability in Global Supply Chains

- Impact of Tariffs and Trade Wars

- The Agility of Supply Chains in Crisis Management

- Related Content

Globalization of Supply Chains

Transforming Supply Chains in a Globalized World

Supply chains have also undergone a profound transformation in an era when the phrase ‘global village’ shifts from metaphor to reality. The intricacies of globalization reach into the heart of production, distribution, and consumption, altering how businesses operate on a vast and diverse scale. Understanding these changes isn’t just about keeping up with the times—it’s about harnessing them for success.

Let’s cut straight to the chase: Globalization has revolutionized supply chains primarily by broadening the geographic and logistic possibilities for sourcing materials, manufacturing products, and reaching customers. It’s a grand-scale version of shopping around for the best deal—but with multi-million dollar stakes and multifaceted strategies.

The broadened supplier base is a standout triumph of globalization. No longer confined to local or even national boundaries, companies can now source raw materials from the corners of the globe where cost, quality, and production capacity align with business goals. This global sourcing strategy reduces costs, but it’s not without risks. Lingering challenges include managing longer lead times and complex logistics, navigating political and economic instability, and maintaining quality across diverse suppliers.

Manufacturing hasn’t escaped the touch of globalization, either. Offshoring and outsourcing have become commonplace in business vernacular as companies set up production in countries with lower labor costs. This isn’t just a cost-cutting exercise—it’s a strategic move that leverages the specific technological and production capabilities unique to different regions.

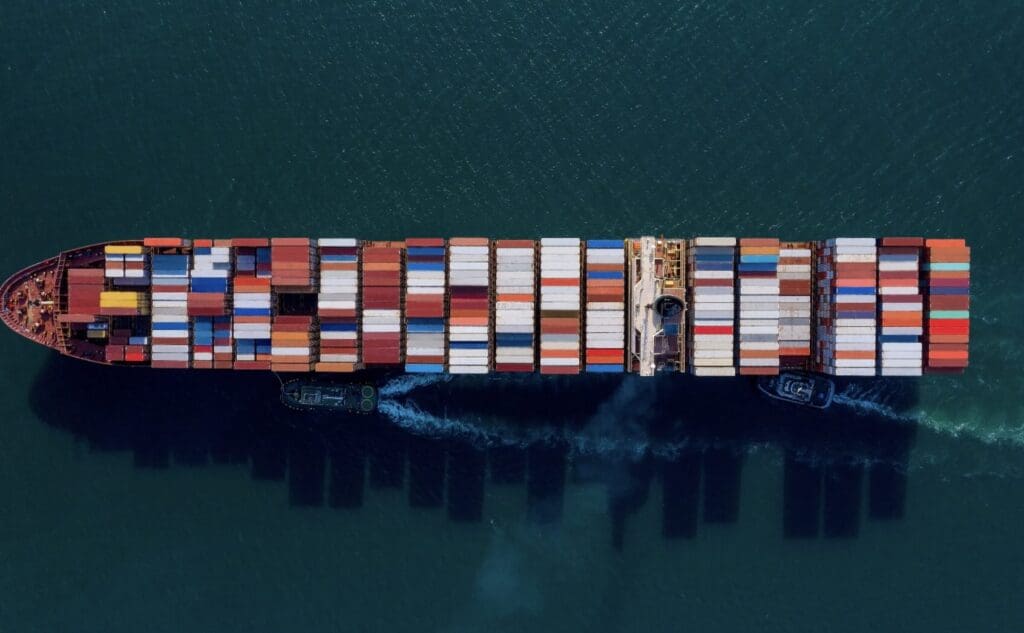

In a global marketplace, reaching the customer is an art form that has had to evolve rapidly. Distribution channels are more intricate, as products often crisscross the globe through intermodal transportation, combining air, sea, rail, and road to deliver products efficiently. This expanded market reach bolsters potential customer bases into the billions—a far cry from the more limited markets of a pre-globalized age.

Then comes the digital revolution, a harmonious companion to globalization that’s given supply chains a cybernetic heartbeat. With real-time data tracking and communication, the logistical dance of moving products becomes a synchronized spectacle. Inventory management, demand forecasting, and order processing now operate on algorithms and analytics that make sense of the sprawling web of global supply chains.

Crucial to the mix is resilience—a quality that global supply chains have had to adopt in the face of international complexity. Diversification is the game’s name, ensuring that when one link in the chain weakens due to unforeseen events—be it a natural disaster, trade war, or a pandemic—others can bear the load, keeping the wheels of commerce turning.

A glance at the landscape of globalization’s impact on supply chains reveals a picture that’s compelling and challenging in equal measure. The agility to adapt, the tenacity to optimize, and the vision to innovate separate thriving enterprises from those left behind. In a world interconnected economically, politically, and technologically, supply chains have become threads in a continually woven tapestry, reflecting the dynamic narrative of globalization itself.

Let’s embrace change, mitigate risks, and optimize the interconnected paths that products travel—from sourcing to manufacturing to the hands of the consumer. There’s no turning back the clock; let’s wind it up and watch it go, taking the global stage at full stride.

Risk Management in Global Supply Chains

Navigating Risks in the Global Market: Essential Strategies for Businesses

The quest for dominance in a global market introduces unique challenges, mainly when orchestrating sophisticated operations across international borders. One pivotal concern facing businesses today is the fluctuation of currency rates. Exchange rate volatility can quickly erode profit margins, leaving companies scrambling to recalibrate prices or renegotiate contracts. To counteract these financial fluctuations, savvy businesses often employ hedging strategies. Firms can lock in exchange rates by leveraging financial instruments such as forward contracts or options, effectively insulating themselves from unwelcome surprises.

Another lurking danger is the complexity of regulatory compliance across different regions. Each country’s laws and regulations can be as diverse as its culture, making compliance a moving target. Businesses must be meticulously attentive to these requirements to avert fines or legal roadblocks, which can manifest as costly delays or damage to reputational assets. Staying abreast of regulation changes through constant monitoring and leveraging legal expertise is critical for maintaining compliance and avoiding punitive repercussions.

Cybersecurity also ascends to the forefront of risks in a hyper-connected world. As supply chains embrace digital infrastructure, the surface for potential cyber threats expands. Data breaches or system hacks can lead to substantial financial losses and jeopardize sensitive information. Robust cybersecurity measures, including regular system audits, employee training, and investing in cutting-edge security technology, are non-negotiable investments for businesses guarding against cyber threats.

Quality control presents another conundrum. When products are made continents away, maintaining consistent quality can be like trying to hit a bullseye during a gale. However, businesses can navigate these choppy waters by implementing stringent quality assurance processes and holding suppliers to exacting standards through regular inspections and audits. By doing so, companies can mitigate the risk of defects and recalls that could tarnish brand reputation.

As businesses chart their course through the global marketplace, the need for cultural adeptness becomes increasingly apparent. Understanding local customs, consumer behaviors, and business etiquette is not just beneficial—it’s imperative for the success of any venture aiming to make a global impact. This cultural intelligence can be honed by building a diverse team with local insights and experiences, ensuring messages resonate and relationships flourish in each unique market.

Lastly, while many businesses focus on risk identification and prevention, they must also devise robust contingency plans for when the unexpected strikes. Whether it’s a natural disaster or a sudden shift in the political climate, companies with comprehensive emergency protocols and business continuity plans tend to navigate crises more effectively and emerge resilient.

In conclusion, businesses operating on the global stage must confront many risks, from financial volatility and complex regulations to cybersecurity threats and quality control challenges. However, companies can survive and thrive in the competitive global marketplace by employing strategic hedging, ensuring regulatory compliance, fortifying cybersecurity defenses, maintaining stringent quality, embracing cultural intelligence, and preparing for contingencies.

While demanding in their implementation, these strategies are the bulwarks that will safeguard businesses and enable them to capitalize on the vast opportunities a globalized economy offers. Embracing these practices will position enterprises for enduring success, armed against risks and poised for innovation.

Technology’s Role in Supply Chain Management

Technology is the linchpin in transforming supply chains worldwide in today’s fast-paced business landscape. Advanced technological solutions are not just add-ons; they’re critical tools redefining the very fabric of supply chain management.

Artificial intelligence (AI) and machine learning catalyze a grand shift in predictive analytics. With AI at the helm, companies are now predicting supply chain disruptions before they occur, allowing firms to navigate potential delays with remarkable agility. Imagine the competitive edge a company gains when it anticipates a shortage in raw materials and swiftly pivots to alternative suppliers, all while its competitors are left scrambling.

The realm of robotics and automation in warehouses is no longer the stuff of science fiction. These mechanized marvels streamline operations, slashing the time between order and delivery to a mere sliver of what it once was. Drones, too, are elevating the logistics game, offering last-mile delivery solutions that bring unprecedented speed to customer doorsteps.

Blockchain technology is instilling trust and transparency like never before. Within global supply chains, it creates an immutable ledger that tracks every product’s journey, from sourcing through the manufacturing process to final delivery. This enhances traceability and fortifies the battle against counterfeit goods, a persistent thorn in brand integrity.

Internet of Things (IoT) connectivity is being leveraged to ensure real-time tracking and monitoring of goods. Sensors attached to products or shipping containers provide live data on location, temperature, and handling conditions, ensuring product integrity throughout the journey.

Cloud computing is revolutionizing supply chains by democratizing access to cutting-edge management systems. Small and mid-sized enterprises now harness robust software solutions that were once the exclusive domain of industry giants. This shift levels the playing field, enabling agility, efficiency, and collaboration on a scale previously unattainable for these smaller players.

The need for tech-savvy professionals grows as supply chains morph into digitally-driven ecosystems. Tomorrow’s supply chain leaders must merge their understanding of traditional logistics with a mastery of digital tools. Their expertise will guide the navigation through a landscape where data-driven decision-making and real-time responses are the norm.

A culture that embraces continual innovation and learning is essential to ensure these technological advancements bear fruit. Companies that cultivate such an environment will survive and thrive in the era of tech-driven supply chains. Each breakthrough is an invitation to reimagine and reinvent the processes that keep the world’s goods moving. It’s a call to step up, innovate, and lead the charge toward a future where supply chains are efficient but also resilient and sustainable.

Indeed, technology is not simply revolutionizing supply chains; it’s redefining the boundaries of what’s possible in global commerce. The dynamism and flexibility afforded by these tech solutions are breaking new ground, ensuring that supply chains remain the lifeblood of businesses eager to excel in an ever-evolving marketplace.

Sustainability in Global Supply Chains

Embracing Sustainability in Supply Chains: The Green Wave in Global Trade

As global commerce surges forward, the reverberations of environmental impact echo louder than ever. There lies an unequivocal truth—sustainability is a moral imperative and a strategic advantage in modern supply chains. The shift toward green logistics opens avenues for business differentiation, cost savings, and brand elevation that resonate with eco-conscious consumers.

In the drive toward eco-friendly operations, businesses amplify resource efficiency and dive into the circular economy. Innovating to extend product life cycles, implementing recycling programs, and fostering a recycling mindset can revolutionize how goods are consumed and disposed of. It’s about spearheading a movement where products are designed with their eventual end-of-life in mind, embracing a regenerative approach that minimizes waste.

Energy efficiency and renewable resources are the lifeblood of sustainable supply chains. Embracing solar, wind, and other green energy sources reduces carbon footprints and can shield companies from the volatility of fossil fuel markets. Streamlining energy use across transportation and warehousing can lead to significant cost reductions, making the pursuit of sustainability a sound financial decision.

The greening tide also demands meticulous scrutiny of vendor practices. Aligning with suppliers and manufacturers that share a commitment to environmental stewardship fortifies the supply chain against reputational risks. It’s becoming increasingly clear that sustainability certifications and eco-friendly credentials bolster brand image and consumer trust.

The packaging stands as a silent sentinel in the sustainability narrative. The evolution toward biodegradable, recycled, or minimalistic packaging solutions reflects a brand’s dedication to planetary health. Optimizing packaging reduces environmental burdens and can cut shipping costs through improved space utilization.

Transportation is also undergoing a sustainability transformation. Advancements in fuel-efficient and electric vehicles are paving the way toward a lower-carbon logistics sector. Companies must constantly evaluate their shipping strategies, consolidate shipments, and optimize routing to minimize emissions and expenditures.

The sustainability journey in supply chains calls for a cultural metamorphosis within organizations. Instilling values that prioritize ecological considerations into every decision can unleash innovation and attract talents passionate about making a difference. Creating cross-functional teams to oversee sustainability initiatives ensures the green ethos permeates the company and propels collective progress.

To encompass sustainability, companies must look beyond the immediate boundaries of their operations, embracing a broader sense of social responsibility and investing in community development. They must also advocate for fair labor practices and participate in global discussions about environmental regulations to position businesses as leaders in the grand scheme of global sustainability.

Reimagining supply chains through the lens of sustainability is no longer a futuristic ideal; a present-day necessity shapes industry leaders. From integrating renewable resources to enforcing responsible sourcing and pushing innovation in packaging and transportation, a sustainable supply chain is a well-oiled mechanism with the power to redefine the market landscape. With relentless pursuit and unwavering commitment, businesses can sail ahead on the green wave, steering global trade toward a brighter, cleaner future.

Impact of Tariffs and Trade Wars

Understanding the Impact of Tariffs and Trade Tensions on Supply Chains

Navigating the wavy seas of global economics, tariffs, and trade tensions significantly impacts international supply chains. These financial tools wield power, altering the cost landscape for importing and exporting goods—an effect felt across the board, from multinational corporations to small businesses seeking a piece of the global pie.

Let’s break down how these tariffs and trade tensions influence the well-oiled machine that is the global supply chain.

First up, tariffs, those pesky little fees tagged onto goods crossing borders, act like speed bumps on a highway, slowing down trade flow and often leading to traffic, or in this case, higher costs for consumers and businesses. These can force companies to rethink sourcing strategies, causing a ripple effect that can reset the entire global supply chain equilibrium.

When countries clash over trade, supply chains bear the brunt. Trade tensions, like a high-stakes chess match between economic superpowers, can prompt businesses to scout alternate routes, circumventing the barriers and keeping their goods moving. While this constant shape-shifting keeps the global economy on its toes, it doesn’t come without costs or delays.

Incorporating tariffs into pricing strategies requires a blend of anticipation and reaction. Companies must remain nimble, adjusting costs accordingly and potentially passing these on to consumers, keeping their margins in the black. It’s akin to a financial acrobat, balancing gracefully on a tightrope of market demands and ever-changing trade policies.

On a broader scale, tariffs and trade tensions can reshuffle global alliances. Traditionally, long and complex supply chains may shift toward regionalization as businesses look to minimize risks and safeguard their processes against political unpredictability. Companies are building buffer zones, hedging against potential trade standoffs that could freeze their operations and choke revenue streams.

Furthermore, the predictability and stability the market craves when trade tensions escalate become distant dreams. Investments in new markets or expansion plans can stall as businesses are hesitant to pour resources into a volatile environment, and the muddied waters of international relations can obscure even the most seasoned business navigator’s vision.

Adaptability of supply chains in the face of trade policy upheavals is not just a bonus but a necessity, cultivating resilience against the winds of economic change. Whether pivoting production, diversifying supplier bases, or rejigging transport logistics, a proactive approach to managing trade-related disruptions keeps businesses afloat.

The grand chess game of global trade is about making calculated moves with precision and foresight. Tariffs and trade tensions serve as both the game pieces and the players, influencing decisions and shaping the architecture of international supply chains. Businesses that master the art of agility and play the long game with an eye on adapting to these financial levers can navigate choppy economic waters, emerge less scathed, and continue charting a course toward prosperity.

There you have it—the intertwined dance of tariffs, trade tensions, and supply chains. In a world where economic landscapes shift with the political climate, those in charge of supply chain management must march to the beat of a drum that can change tempo at a moment’s notice, ensuring that their operations can withstand and adapt to the global market’s melodies.

The Agility of Supply Chains in Crisis Management

Navigating Global Crises with Agile Supply Chains

Global crises, whether economic downturns, health emergencies, or political unrest, challenge the robustness of supply chains worldwide. The key to weathering these torrents is an agile approach. An agile supply chain is nimble, responsive, and able to pivot in real-time, which is essential when faced with rapidly changing global circumstances.

But what does agility look like in practice, and how can it provide an advantage during crises?

Let’s delve into real-time data analytics. An agile supply chain leverages up-to-the-minute data to make informed decisions quickly. During a crisis, variables change with unnerving speed. Real-time analytics allow businesses to forecast demand, manage inventory levels, and allocate resources dynamically, often using advanced software systems.

Next, risk management takes center stage. Agile supply chains conduct scenario planning and have contingency measures already in place. These ‘what-if’ strategies help businesses anticipate potential disruptions and implement responses proactively. Risk management also covers diversification in procurement strategies — not putting all eggs in one basket reduces the impact of a crisis on any single node within the supply chain.

Collaboration is another cornerstone. Agile supply chains thrive on strong, transparent partnerships with suppliers, distributors, and logistics providers. When crisis strikes, these relationships foster open communication, enabling rapid collective action. Shared information systems among partners can streamline coordination, so when one part of the network falters, others can step in without delay.

The human element should not be overlooked. An agile supply chain invests in continuous staff training, ensuring a workforce that can adapt to new technologies and processes quickly. In times of crisis, a skilled and flexible team is invaluable, able to tackle unfamiliar problems and implement inventive solutions.

Customer-centricity is the pulse of agility. Supply chains designed with the end user in mind can better maintain service levels during disruptions. This customer-first mindset drives a continuous feedback loop, aligning the business with evolving market needs and expectations.

Finally, agility does not compromise on values. Even amid a crisis, sustainable practices and ethical considerations remain integral. An agile supply chain isn’t opportunistic. Instead, it balances efficiency with environmental responsibilities and community impacts, ensuring long-term brand integrity and customer trust.

Adapting to and emerging stronger from global crises is no small feat. It necessitates embracing flexibility, state-of-the-art technology, and collaboration, all underpinned by a culture that thrives on change. With these agile foundations, supply chains can survive today’s crises and shape tomorrow’s resilient commercial landscapes.

As the journey through the maze of global supply chains concludes, it’s clear that the threads binding the international economy are robust and vulnerable. Navigating this intricate network requires a multifaceted approach that balances innovative technologies, sustainable practices, and strategic crisis management.

Faced with the dual specter of trade disputes and potential global crises, businesses are tasked with continuous adaptation to maintain the steady flow of commerce that sustains economies worldwide. The agility, foresight, and flexibility demonstrated within effective supply chains are not merely assets but necessities for any organization aspiring to excel on the world stage. Embracing these principles will align businesses with global trade currents and secure their position as formidable players in the shifting sands of the international marketplace.

Find out more about how Mondoro can help you create, develop, and manufacture excellent home decor and furniture products – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal. You can find it on all major podcast platforms. Try out listening to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel with great videos and information by clicking here.

Related Content

High Point Furniture Market, Insider Tips And Guide

I have attended the High Point Furniture Market twice a year for almost 30 years. During this time, I have learned some of the best ways to attend the market, and what first-time or any market attendees should do. If this is your first time at the High Point Furniture market, most people do not realize how huge the market is, so you need to plan, be prepared, wear comfortable shoes, and know what you are looking to buy or accomplish at the market.

You can learn more by reading High Point Furniture Market, Insider Tips And Guide by clicking here.

Where Do Small Furniture Stores Get Their Furniture?

Many small furniture stores will buy their products wholesale from a wholesale furniture company. Many companies in the United States wholesale furniture to small furniture stores. Other small furniture stores may decide they want to manufacture or produce the products themselves. Successful stores have used both methods to source furniture for them to sell in their store.

By clicking here, you can learn more by reading our blog, Where Do Small Furniture Stores Get Their Furniture? by clicking here.

Where To Buy Home Decor Items For Retail Or Your Online Store?

If you are looking to start an online or retail store, one of the most significant issues that most people face is knowing where to buy the home decor items for their online or retail store. We have been producing home decor products for over 20 years; we have experience in knowing where to buy home decor items.

You can learn more by reading our blog, Where To Buy Home Decor Items For Retail Or Your Online Store?, by clicking here.