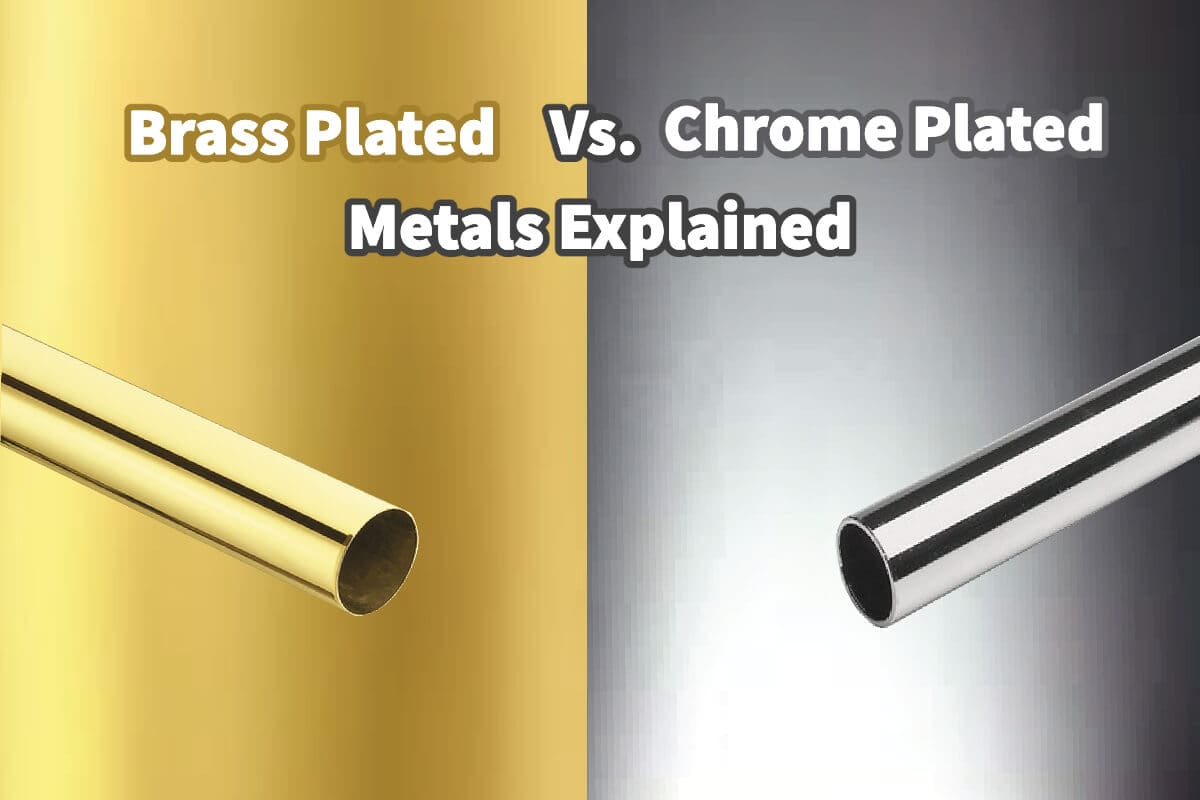

Brass and Chrome-plated metals are two trendy metal-plated finishes used for various products, looks, and designs.

Brass and Chrome are plated on metal using electroplating, but the look and finish are not the same. Brass will be warm golden, whereas Chrome will look like shiny silver metal. Both are electroplated treatments, so choosing one depends on your desired look for a specific product.

Table of Contents

- Brass Plating Vs. Chrome Plated Metals

- Plating Of Brass And Chrome

- Chrome Plating On Solid Brass

- 10 Reasons Metal Is Plated

- Frequently Asked Questions

- Related Content

Brass Plating Vs. Chrome Plated Metals

Brass plating and chrome plating are both metals that are electroplated. Electroplating is when the metal finish is put on top of another metal or other materials.

Brass is a warm yellow-brown color, and chrome will be a shiny silver metal finish. Even though they are both metal-plated, the look and color of each of them are very different.

The plate technique or the electroplating of Brass and Chrome would be similar even though the result and color are different.

Brass Plated Metal

Brass plating is one of the most widely used methods due to its color and brass plated appeal for decorative purposes. Usually, brass-plated items are sprayed with a lacquer topcoat to prevent tarnishing and discoloration.

Brass plating is done from a cyanide solution containing a mixture of copper and zinc cyanides. The amount of each of these in the electroplating bath can vary greatly.

One of the reasons brass plating is so popular is that you can get the brass look and feel of an item without solid brass. Also, the plating still allows you to have a variety of finishes on the brass, such as matte brass, high shine brass, antique brass, and brushed brass.

Because of all the finishes you can create with brass, it is an ideal metal for home decor and home furnishing products, including decorative hardware for furniture and accessory items.

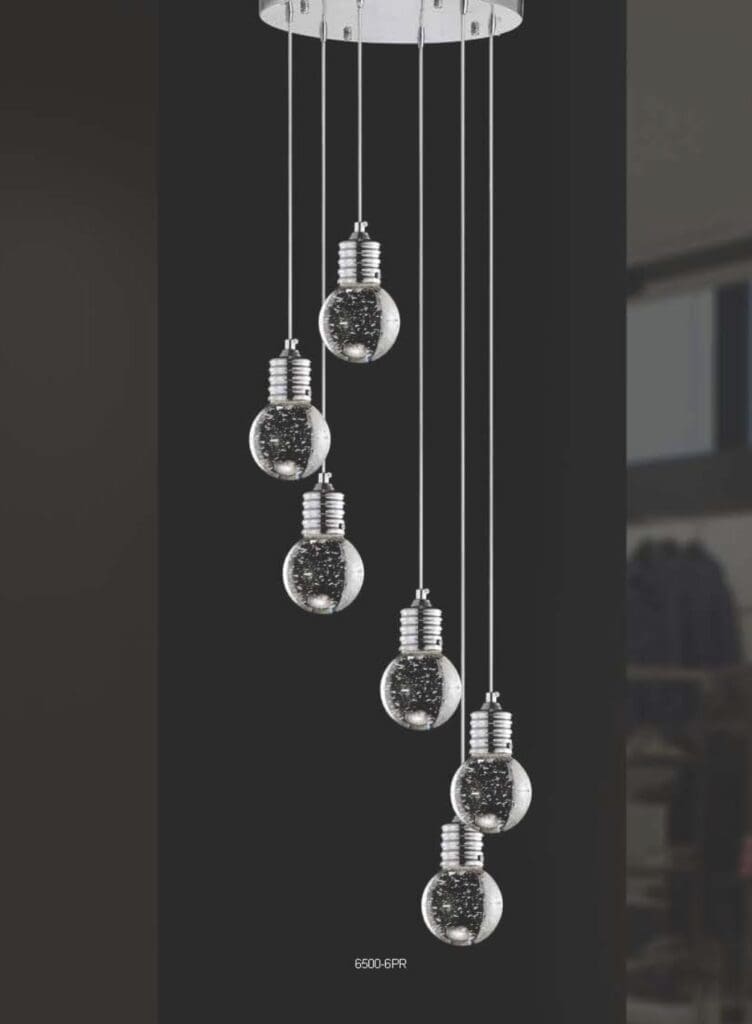

Chrome Plated Metal

Chrome plating is also a plated metal finish. It is less commonly called chromium plating. Chrome plating is accomplished by plating a thin layer of chromium oxide on a metal object.

Chrome plating is used a lot for decorative elements as it is both pleasing and durable at the same time. It is usually plated on metals such as steel, aluminum, plastic, copper alloys, and zinc alloys.

Chrome plating is always corrosion-resistant often used on car parts, tools, and kitchen utensils. To some extent, chrome may be used for decorative hardware in the home furniture and furnishing industry.

Plating Of Brass And Chrome

The technique to plate both Brass and Chrome would be done by electroplating. Even if the look and color result is very different between Brass and Chrome, the finish process is similar.

Electroplating Process Defined

Plating is also known as electroplating. The Oxford Dictionary defines electroplating as:

“coat (a metal object) by electrolytic deposition with chromium, silver, or another metal.”

Oxford Dictionary

In simple terms, electroplating is when a metal coating is placed onto a metal or another kind of material to coat or put on a finish. There are many reasons why it can be good to Electroplate vs. having a solid metal, which include:

- Decorative Purposes – Electroplating is done on metal to give the metal a specific look or feel.

- Cost – Electroplating or a plated finish is usually cheaper than solid metal. An example of this is plated brass is usually cheaper than solid brass.

- Corrosion – Many electroplated metals have better resistance to corrosion and abrasion.

- Recoat Old Parts – Sometimes, older parts are electroplated to build up the thickness of the older part or piece.

Electroplating Steps Reviewed

The process of electroplating would be the same for brass and chrome plated. The process to electroplate is as follows:

- Metal Preparation – The metal would first need to be prepared for electroplating.

- Cleaned – To plate metal, the metal would need to be cleaned. To ensure that the object or metal is cleaned, it is placed in a cleaning solution.

- Plating Set Up – The negative and positive electrical lead substrate is connected to the metal. The negative and positive substrate helps set up the plating process.

- Plate Bath – The plate bath deposits begin, exposing the object to a current. The more current, the thicker the plating will become.

- Plate Post-Treatment – The plate post-treatment step is when the object has a coating treatment to prevent tarnishing and improve the overall corrosion resistance.

As the Electroplating material can create waste material, once the process is completed and the material we can not use anymore, we will properly dispose of it.

Whether you are plating a brass or chrome finish, the process to plate them is the same. The main difference is the kind of material used for the plating.

Chrome Plating On Solid Brass

Sometimes, people will want to have brass fittings but with chrome color. Solid brass with a chrome finish is used for faucets, pipes, and plumbing. Also, sometimes for musical instruments.

The advantage of this is that you can have the natural malleable durability of brass while at the same time having the shiny chrome silver finish.

Depending on what you need it for or want some chrome-plated brass fittings, this could be the way to go when wanting a brass object in a shiny silver finish.

10 Reasons Metal Is Plated

Plating metals, such as brass plating or chrome plating, offer several advantages and are used in various industries for a multitude of reasons. Here are ten reasons why metals are often plated:

- Corrosion Resistance: One of the primary reasons to plate metal is to provide a protective layer that prevents the underlying metal from corroding. Chrome, for instance, offers excellent corrosion resistance.

- Aesthetics: Plating can enhance the appearance of metal objects. A shiny, reflective chrome or brass finish can be much more appealing than the dull appearance of many base metals.

- Wear Resistance: Some plating materials can significantly increase the wear resistance of the object, reducing the wear and tear it might experience in regular use.

- Improved Electrical Conductivity: Certain plating materials, such as gold or silver, can enhance the electrical conductivity of electronic components.

- Reduced Friction: Some plated coatings can reduce friction, which is beneficial in applications like engine parts or other machinery components where reduced friction can enhance efficiency and longevity.

- Chemical Resistance: Plated coatings can offer resistance against chemicals, making the plated items suitable for environments where they might come into contact with corrosive substances.

- Adhesion: Some manufacturing processes require metal to be plated first to ensure that subsequent coatings or treatments adhere better to the surface.

- Solderability: In electronics, metals like tin or gold might be plated onto components to ensure they can be easily soldered to other components.

- Cost Efficiency: Sometimes, it’s more economical to manufacture an object using a cheaper base metal and then plate it with a thin layer of a more expensive, desirable metal. This provides the appearance and some properties of the more expensive metal without the cost of making the entire object out of it.

- Health and Safety: Certain base metals might leach or react with substances they come in contact with, especially in food and beverage applications. By plating these metals, it’s possible to ensure a safer interaction between the metal and its environment.

Metal plating is essential in various industries, offering functional and aesthetic advantages to a wide range of products.

To learn more about how Mondoro can help you create, develop, and manufacture excellent home decor and furniture products – including brass or chrome objects – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal. You can find it on all major podcast platforms. Try out listening to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel filled with great videos and information by clicking here.

Frequently Asked Questions

What is chrome-plated brass?

Chrome-plated brass is a type of metal with a chrome layer applied to its surface. The underlying material is typically brass, a copper-zinc alloy.

What are the benefits of using chrome-plated brass?

Chrome-plated brass is highly resistant to corrosion and tarnishing, which makes it a popular choice for decorative and functional applications. It also has a bright, reflective surface that is easy to clean and maintain.

What are the differences between chrome and brass?

Chrome is a metal with a bright, reflective surface that is highly resistant to corrosion and tarnishing. Brass, on the other hand, is a copper-zinc alloy with a yellowish color that can tarnish over time.

Can brass be chrome-plated?

Yes, brass can be chrome-plated to give it a bright, reflective surface that is highly resistant to corrosion and tarnishing

How is chrome-plated brass made?

Chrome-plated brass is made by electroplating a layer of chromium onto a brass substrate. The process involves immersing the brass object in a bath of chromium plating solution and passing an electrical current through it.

What are some common uses for chrome-plated brass?

Chrome-plated brass is commonly used in plumbing fixtures, automotive parts, and decorative hardware. It is also used in the manufacture of musical instruments and jewelry.

Is chrome-plated brass durable?

Yes, chrome-plated brass is highly durable and can withstand exposure to moisture and other environmental factors. It is also resistant to scratching and wear.

Can chrome-plated brass be polished?

Yes, chrome-plated brass can be polished to maintain its shiny appearance. However, it is important to use a non-abrasive polish to avoid damaging the chrome plating

How do I clean chrome-plated brass?

Chrome-plated brass can be cleaned with a mild soap and water solution or a non-abrasive cleaner specifically designed for chrome surfaces. Avoid using abrasive cleaners or steel wool, which can scratch the chrome plating.

Related Content

What is the Brass and Bronze Material Used In Home Decor Products?

Brass and bronze are copper alloys, brass, and zinc; bronze material is copper and tin. They both look similar but have different properties and uses. When brass or bronze is made into home decor products, they will often be sand cast or use a lost wax or investment mold technique. Each production method has different uses, and prices can affect the overall production.

You can discover more by reading What is the Brass and Bronze Material Used In Home Decor Products? by clicking here.

Are Brass And Nickel The Same?

Both Brass and Nickel are metal finishes that can be electroplated or plated. They contain copper and can be made into various unique and exciting looks and finishes. Because of their versatility, they remain popular metals and finishes for various products and uses.

You can find out more by reading our blog Are Brass And Nickel The Same? by clicking here.

Is Nickel A Natural Element? All About Nickel and Its Everyday Uses

Nickel is a natural element as it is found in nature. It is a challenging yet malleable, ductile metal with shiny silver color and a slight gold tinge. Nickel is found mainly in Russia, South Africa, Canada, Australia, and some parts of China and Vietnam.

You can discover more by reading Is Nickel A Natural Element? All About Nickel and Its Everyday Uses by clicking here.