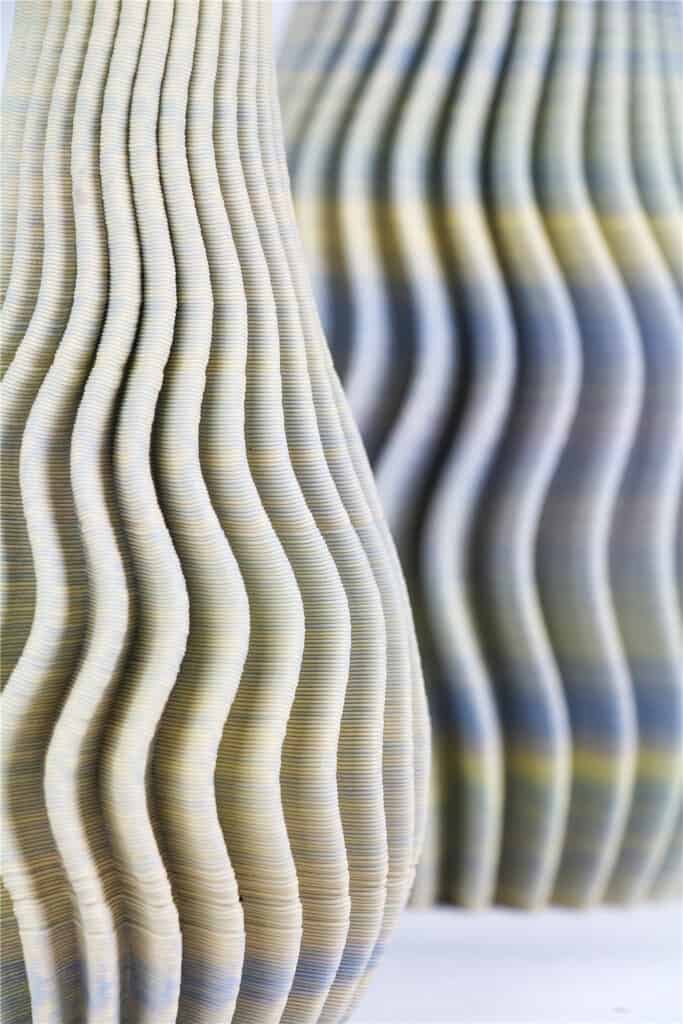

There is a new kind of technology-based porcelain manufacturing that is known as 3D porcelain. The reason it is known as 3D porcelain is that the porcelain is produced in 3-D shapes with a lot of interesting dimensions.

Home decor and home furnishing products in 3-D continue to be an important home decor trend. Many types of home furnishing products use 3-D elements. The 3-D porcelain is a very unique product in that it uses modern-day computerized technology to efficiently produce a variety of 3-D shapes and sizes.

Table of Contents

Any company that manufactures this kind of production must have enough 3-D machines and also a large enough kiln to fire these porcelain pieces efficiently.

The 3-D Porcelain Trend

A trend that continues in home decor and home furnishing is the 3-D trend or having some texture on your home decor accessories or furniture products. This trend has been coming about as technology has also improved for things like 3-D printers.

Mariana Bettinelli, an Italian blogger and influencer, wrote in her blog Interior Notes about some of her observations from attending the Milan Design Week. In her blog, she mentioned she saw as one of the trends 3-D elements being used by many designers. This is what Mariana Bettinelli said:

“TEXTURE AND 3D SURFACES: I spotted a lot of 3d surfaces with a material effect, such as for example the Mooi 3D wallpapers, Salvatori’s marble cladding, frosted or 3D-effect glass or wavy surfaces. These last ones, in particular, have been used a lot and personally I really like them (the blu corrugated metal walls used by Masquespacio were beautiful)

Mariana – Interior Notes

We believe that the trend of using interesting textures, 3-D elements, and having unique shapes and sizes will be a trend that will continue in home decor and home furnishing for many years to come.

3-D Porcelain and Ceramics

3-D porcelain production is quite an intricate process of porcelain manufacturing. It is a very new and exciting way to make porcelain shapes and pieces.

Many of the best manufacturers who are doing the intricate 3-D porcelain work are using a machine to help them manufacture the porcelain into various shapes and sizes. These 3-D porcelain machines are an example of using technology to make some very interesting shapes and sizes.

Watch a Video To See The Production Process

You can watch our short video below (click on the video) It shows you these machines that are making 3-D porcelain.

We love these new porcelain machines and how they are able to be computer programmed to make precision 3-D porcelain shapes and designs. Not only is this a great trend in manufacturing, where manufacturers are scaling production to be as automatic as possible, but it also allows us to do shapes and intricate designs that cannot be done economically any other way.

The machines they are using are all computerized so that each piece will be exactly the same. This is important as you want the pieces to be as accurate as possible regarding size, color, shape, and composition. In other words, when programmed correctly, the computer will be doing all the work to make sure the 3-D porcelain pieces are exactly the same.

The manufacturer we are working with has about 100 to 200 machines, so this gives them an advantage in that they are able to produce enough quantities with their machines. A total of 100 to 200 machines, if operated full-time, are about the same as having 500 to 600 factory workers.

Many factories only have a few machines, and this means they can make a sample, but production is much harder. But, just having the machine for this production is not enough. In order to ensure the 3-D porcelain pieces will fire correctly, the manufacture must also have a very large size kiln. Our manufacturer has this large size kiln.

So to sum up, what is needed to produce this kind of 3-D porcelain 1 economically) the manufacturer must have enough 3-D porcelain machines, and 2) and must also have a large-scale kiln to fire the 3-D porcelain.

This kind of production just can not be produced economically with a small-scale kiln. It is also because of the kiln size that we need to have a total of about 300 pieces of one shape to produce this kind of production economically. The one shape and size can be a variety of colors. So, for example, we could manufacture 300 pcs of 3 different colorways or 100 pieces per each color.

If you are interested in finding out more about how to porcelain kilns and what happens when ceramics and porcelains are actually fired, you can read our blog on How Does The Firing Temperature Affect Ceramics Production? by clicking here.

We believe 3-D porcelain in a variety of colors, shapes, and sizes can be a great addition to any home decor and home furniture collection. The 3-D porcelain product shows how the ancient craft of porcelain manufacturing can be scaled up to take into account the technology of today.

Find out more about how Mondoro can help you create, develop, and manufacture excellent home decor and furniture products – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal. You can find it on all major podcast platforms. Try out listening to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel with great videos and information by clicking here.

Frequently Asked Questions

What is 3-D Porcelain Manufacturing?

3-D Porcelain Manufacturing refers to the production of porcelain products using modern computerized technology that enables the creation of intricate and three-dimensional shapes. This innovative process allows for the efficient production of unique and varied designs.

How is 3-D Porcelain Different from Traditional Porcelain Manufacturing?

Unlike traditional porcelain manufacturing, which typically involves molding and casting, 3-D porcelain manufacturing utilizes computerized technology to create intricate three-dimensional shapes. This results in a more dynamic and modern aesthetic for porcelain products.

What Types of Products Are Made Using 3-D Porcelain Manufacturing?

3-D porcelain technology is versatile and can be applied to various home decor and furnishing products. Common items include vases, tiles, decorative elements, and other home accessories that feature intricate and detailed three-dimensional designs.

What Are the Benefits of 3-D Porcelain Manufacturing?

The key benefits of 3-D porcelain manufacturing include the ability to produce complex and detailed designs with precision, increased efficiency in the manufacturing process, and the creation of unique and modern home decor items.

How Does Computerized Technology Play a Role in 3-D Porcelain Manufacturing?

Computerized technology is integral to 3-D porcelain manufacturing as it allows for the precise design and execution of three-dimensional shapes. Designers use specialized software to create digital models, which are then translated into physical products using advanced manufacturing equipment.

Can Custom Designs Be Created Using 3-D Porcelain Manufacturing?

Yes, one of the advantages of 3-D porcelain manufacturing is the flexibility to create custom designs. Designers can use computer software to craft unique and personalized porcelain products tailored to specific preferences and requirements.

Is 3-D Porcelain Limited to Specific Colors and Finishes?

No, 3-D porcelain manufacturing allows for a wide range of colors and finishes. The versatility of the technology enables the production of porcelain products in various shades, patterns, and textures to suit different styles and preferences.

Is 3-D Porcelain Environmentally Friendly?

The environmental impact of 3-D porcelain manufacturing can vary depending on factors such as materials used and production processes. Some implementations may prioritize sustainability by using eco-friendly materials and minimizing waste through efficient production methods.

Is 3-D Porcelain More Expensive Than Traditional Porcelain?

The cost of 3-D porcelain products can depend on factors such as design complexity, materials used, and the overall production process. While some customized or intricate designs may be priced higher, the efficiency of the manufacturing process can also contribute to competitive pricing.

Where Can I Find 3-D Porcelain Products?

3-D porcelain products can be found in specialty home decor stores, online marketplaces, and from manufacturers specializing in this technology. Additionally, some interior design and home furnishing retailers may offer a selection of 3-D porcelain items for purchase.

Related Questions

What Is The Difference Between Earthenware, Stoneware, and Porcelain Materials?

Whenever anyone talks about earthenware, stoneware or porcelain pottery or ceramics there can be a lot of confusion about what each product is and how each material is used. Earthenware, stoneware, and porcelain are all made by various kinds of clays and then fired in a kiln. The kind of clay that is used and the temperature they are fired at can make a difference as to how soft or hard the actual end product is. Porcelain is fired at the highest temperature, and so it is the hardest material of these three kinds of materials and clays. Though all three kinds of material can seem to be similar, they are, in fact, all very different kinds of materials.

To find out more about this you can read our blog Earthenware, Stoneware, and Porcelain Materials by clicking here.

What is Outdoor Lightweight Concrete?

Lightweight outdoor concrete is mixed using cement and coconut fiber dust. The coconut coir dust is a natural material that is made from real coconut shells. As the coconut shells are usually agricultural waste, the coconut dust is considered an upcycled material. The lightweight concrete has strength and toughness and is relatively crack-free, so it can be used in a variety of home decor and home furniture products.

To find out more about the outdoor lightweight concrete you can read our blog Outdoor Lightweight Concrete Furniture, All You Need To Know by clicking here.