The most challenging thing for many companies within the supply chain is to find suitable sources or, in other words, to procure the correct products. Sourcing or procurement affects almost every company and business in some way.

A seven-step strategic sourcing strategy process will help companies succeed when procuring a product or a commodity. If companies take the time to go through each of the seven steps, this will help them to ensure they are successful with their sourcing needs.

Table of Contents

Guide to the Seven Steps of Strategic Sourcing

Introduction Rewrite: “For many businesses, a major challenge in the supply chain is identifying and securing the right sourcing options for their needs. Procurement is a critical aspect that impacts virtually every business sector.

To navigate this complex landscape, a structured approach is essential. This is where a seven-step strategic sourcing process comes into play, providing a comprehensive framework to aid companies in successful procurement endeavors.

By meticulously following these seven steps, businesses can enhance their sourcing strategies, avoid common pitfalls, and ensure they meet their sourcing requirements effectively. This guide outlines these steps, offering valuable insights into each stage of the strategic sourcing process.”

Below are the steps of the strategic sourcing process explained:

Step 1 – Identify What You Will Source

The first step is identifying what product or commodity you need to source. Here are a few things that you should look at:

- Product Specifications – The first thing you need to look at is your product specifications. What size do you need? What type of quality? Do you need any other specifications for this product or commodity? All of these things are questions that you need to consider.

- Use of Product – Does it need to define how you are going to use the product clearly? Is this something you were going to need to frequently purchase? Do you need it as part of your own supply chain or a manufacturing need?

- Volume – You should have a clear understanding of what you are going to buy and how much quantity you need. If you only need to buy one or two items, you may not be able to buy it from a wholesaler. If you need to buy large quantities, it may be more prudent for you to import it.

Step 2 – Analysis Market Supply

Analyzing your market supply will help you clearly understand your market supply and make a difference in your entire sourcing strategy.

As we have seen with many of the recent supply chain bottlenecks, you need to analyze if this is a product you need from overseas or buy locally. Will you be able to receive it in a more timely manner if you purchase it overseas or locally? All these things need to be analyzed with the market supply.

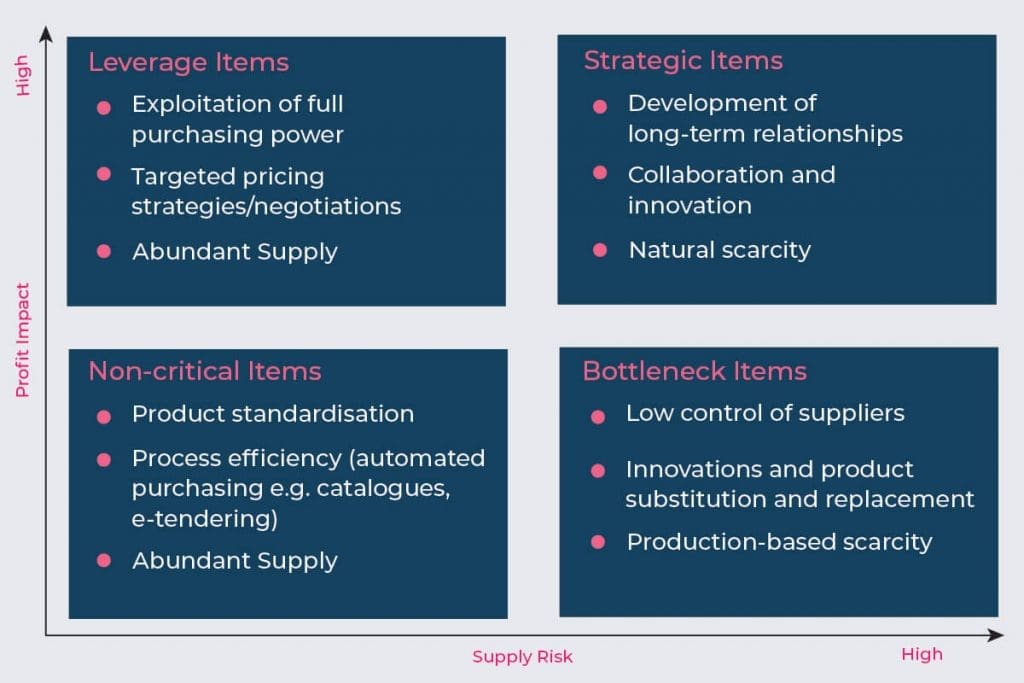

There is a simple matrix known as Kraljic’s Matrix. In 1983, Peter Kraljic argued that supply chain items should consider two critical areas of focus: risk and profitability.

The Analysis Market Supply Matrix by Peter Kraljic

Risks are considered if the supply chain has issues (such as a container shortage or delays) that disrupt operations. Today’s supply chain has seen many risks with container shortages and other uncertainties.

Profitability is the issue of supply chain problems or the company’s bottom line. With this, it could be the cost of shipping goods and products to their destination. We have seen this again play out as container costs rose during the COVID pandemic to rates never before seen.

Kraljic matrix helps us know how risks and profitability can impact a product’s marketing sourcing and supply.

Step 3 – Develop Your Sourcing Strategy

In step three, you start to develop your overall sourcing strategy. Step three will help you decide where and how to buy the product or commodity while considering the risks, cost, and profitability.

During this phase, you consider your business goals and minimum requirements for any product, commodity, or sourcing supplier. You can then list the essential criteria for the company from which you will be sourcing or purchasing the product or item.

Step 4 – Start The Sourcing Process

It is now time for you to start the sourcing process. You will notice that you did not contact any potential suppliers in the first three steps. Instead, it was all about fully understanding what you want to source and why you want to source it.

Step four is where you start to contact companies and ask them to send you a bid or a price for the items you seek.

Step 5 – Negotiate With Your Suppliers

Now that you have contacted several suppliers, you have probably started to narrow down which suppliers you may want to work with. In step five, you begin a negotiation phase and decide who you will buy the product or commodity from and why.

Most types of sourcing will require some negotiation. The negotiations could be for the volume, quantity, price, packaging, or other things you need for your product or commodity. Studying those aspects of the development will ensure that you will get the product at the quality, quantity, and price you expect.

Step 6 – Implementation and Integration

Now that you have finished all the negotiations with the potential suppliers, you start telling those you have decided to purchase from who will be part of your supply chain. Here is where you begin to integrate them as one of your stakeholders.

As you begin integrating and implementing these suppliers as part of your supply chain, you should hold meetings to fully incorporate them so they understand your requirements and their success benchmarks.

Step six is when many people ignore or feel that the supplier should already understand your requirements. But the truth is that different companies will have additional requirements, so it is vital to state your needs clearly.

Step 7 – Give Benchmarks To The Supplier

Many people underestimate the step of giving benchmarks to your new supplier. It is a massive mistake not to share some benchmarks with your new supplier. Providing standards will ensure that you are successful, and they will also be successful as your supplier. A good company will want to do all it can to ensure success.

In the seventh step, you create benchmarks to measure your suppliers’ performance over time. Also, it would be good if you could communicate your expectations to your supplier.

The seven steps of strategic sourcing are set up as a process to help companies to be successful with their sourcing needs. When a company follows these simple seven steps, it will help ensure its sourcing strategy is successful.

If you are interested in seeing how Mondoro can help you with your strategic sourcing – we would love to talk to you about how we can help you.

At Mondoro, we create, develop, and manufacture home decor and home furnishing products.

Find out more about how Mondoro can help you create, develop, and manufacture excellent home decor and furniture products – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal. You can find it on all major podcast platforms. Try out listening to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel with great videos and information by clicking here.

Related Content

Product Sourcing and Strategic Sourcing Explained

Product sourcing is when you source or look to find a supplier for a product you need. Strategic sourcing is strategically sourcing products. Strategic sourcing is not about the lowest purchase price but the lowest overall cost. Product sourcing and strategic sourcing are very similar, but strategic sourcing is sourcing with a plan in place.

You can learn more by reading Product Sourcing and Strategic Sourcing Explained by clicking here.

What Is The Difference Between Supply Chain Management and Logistics?

Supply chain management is about the collaboration and partnerships to get the goods from raw materials to the end consumer; it is about the partnerships and alliances within this process. Logistics is one part of supply chain management; logistics involves moving goods from one place to another. The logistics providers will also store the goods and send them to the end consumer in some instances.

By clicking here, you can learn more by reading our blog What Is The Difference Between Supply Chain Management and Logistics? by clicking here.