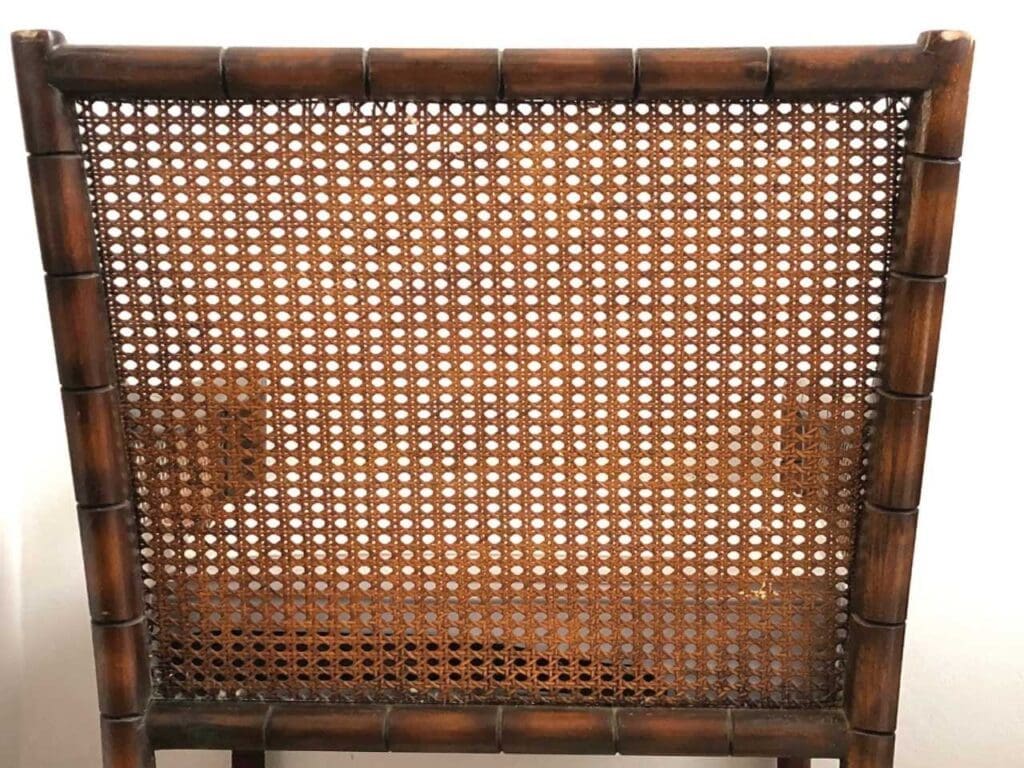

The caning of chairs continues to be a popular look. Caning gives the furniture pieces a natural look and feel.

There are three basic types of caning: hand caning, press caning, or pre-woven cane and rush seats. Each of these has a unique look and feel. Caning and other woven kinds of natural mats have been used on furniture for centuries.

Table of Contents

- Hand Caning Explained

- Pre-Woven Cane Or Press Caning Explained

- Rush Seats Explained

- Other Types Of Natural Weaves

- Related Content

Hand Caning Explained

Hand caning is the traditional way that cane chairs were made. For hand caning, the cane strips are attached to a hole in the bottom of the chair, which is woven by hand.

As the name implies, it is an entirely hand-woven technique. Here are a few things to understand about a hand-caning chair:

- Chair Made For Hand Caning – The chair’s frame must be made for hand caning. You can not just take any chair and decide to turn it into a hand-caning chair. The chair must be designed as a chair that requires hand caning on the seat.

- Holes In Frame Of Chair – For you to do the hand caning, holes must be drilled into the chair’s frame. You will need these holes to put the cane on the chair.

- A Strip Of Cane To Cover Holes – Hand caning usually has a strip of cane to cover the holes of the caning.

- Caning Woven By Hand – The caning for the seat or back of the chair or furniture must then be woven by hand. There is no way to use a machine to weave the cane; this is a hand process.

Most antiques you buy, especially the older ones with a caned seat, are all hand caning. Many of them also need to be re-caned as after a while, due to the wear and tear, the chair seats can start to break.

Pre-Woven Cane Or Press Caning Explained

Today you can also buy pre-woven caning material. Not all caning you buy in a roll is caned by machine; a lot of it I have personally seen is woven by hand.

Press cane, known when the cane is from a roll and not woven into the seat, became famous as an alternative to the more costly and time-consuming hand caning. You can also identify this type of structure as a thin piece of wood at the edge of the chair where the cane joins the frame.

Also, there are no holes in the chair or furniture piece, so the chair can only be re-caned using this method of press caning.

Pre-woven rattan is placed on the furniture differently in that there will be a frame, and the rattan is put onto the chair or furniture piece. This is used a lot today for cane furniture production as it makes more economic sense and is easier in the production process.

Two types of pre-woven rattan are:

Handwoven Pre-woven Cane Or Press Cane

The hand-woven pre-woven cane or press cane is the type of cane I have seen in Asia. This is because it is more efficient to weave a lot of the natural rattan by hand than by machines. There are many reasons for one: the nature of the weaves and the workers’ skills.

Also, the rattan material is not always easy to weave by hand and requires skills. A strip of natural rattan material needs to be woven on the front side (there are two sides to the rattan material).

I have seen hand caning woven on a frame similar to a loom. Below is a video to show the process of hand weaving cane.

Here are reasons why sometimes the rattan is still woven by hand:

- Women Can Weave In Homes – In Asia; many women can set up looms and hand weave the rattan in their homes. This allows them to have an income while also being able to tend to their homes.

- Pick Materials – They can also pick the best materials as they are weaving the rattan to ensure it is rattan of excellent quality.

Machine Pre-woven Cane Or Press Caning

There is also machine-woven caning material. The machine woven can be a natural rattan or faux rattan.

The faux or synthetic rattan is more manageable to weave with the machine than the natural rattan, but faux rattan is not a genuine rattan or a natural material.

Not all rattan you buy in a roll, nor is all rattan put on a chair or furniture piece machine woven. Chances are, if you buy a quality piece of furniture, the natural cane they use is hand-woven with genuine rattan. In our production, we use mainly hand-woven rattan.

Rush Seats Explained

Another popular kind of weave in the cane category is rush seats. Rush seats are not technically cane seats, but many people put them as the third kind of weave as it is a natural weave that is usually on a chair seat.

Like many kinds of caning, different types of rush materials are used to make rush seats. Each of these is different.

Fiber Rush Seats

The fiber rush became used in the early 1900s as a substitute for the natural rush, which was expensive and time-consuming to produce. Fiber rush is a twisted chemical-treated kind of kraft paper in large spools for easier weaving.

An advantage of fiber rush is that it is uniform in size and color, so it is easier to weave than the natural rush. It is usually woven in a pattern with four triangles on the seat.

Genuine Rush Seats

Genuine rush seats are woven from hand-twisted leaves; it tends to be larger than the fiber rush. The rush is not always twisted and sometimes can come out or protrude out of the seat.

Natural rush is usually more expensive and time-consuming than fiber rush.

Pre-Twisted Rush Seats

A pre-twisted rush can look like a genuine rush and is made to look like it. It is a heavier kind of rush that is more uniform than the natural rush.

If you want a natural-looking seat, then the pre-twisted rush is the kind of weave most people will do.

Wheat Wrap Rush Seats

The Wheat wrap rush seats are a material that can be seen on antiques or imported pieces from France, Italy, Spain, and Mexico. It is a straw-like material twisted together and then wrapped with wheat.

It can have a pale green kind of color. This is also a great look as it looks very refined.

Other Types Of Natural Weaves

Besides caning, many other types of weaves are produced similar to caning. They can be hand-woven on a loom or woven by my hand.

Many of these same weaves also make for some great-looking chair seats or as part of a furniture piece.

The natural look continues to be popular, and one of the great looks for this is the caning and other kinds of natural weaves. This can give your furniture piece a natural look and feel.

If you are interested in seeing how Mondoro can help you with your rattan furniture and other home decor products – we would love to talk to you about how we can help you.

Find out more about how Mondoro can help you create, develop, and manufacture excellent home decor and furniture products – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal. You can find it on all major podcast platforms. Try out to listen to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel filled with great videos and information by clicking here.

Related Content

Can You Paint Plastic Rattan Or Faux Rattan Furniture?

The short answer to this is that you should not paint your plastic or faux rattan furniture. The plastic or faux rattan material is not made or manufactured to be painted. If you paint on your plastic or faux rattan furniture, the paint will eventually peel and crack; the painting could also damage the furniture.

You can learn more by reading Can You Paint Plastic Rattan Or Faux Rattan Furniture? by clicking here.

What Is Stronger Rattan Or Bamboo?

Bamboo is stronger than rattan. Some bamboo is known even to have a higher tensile strength than steel; this is why bamboo is used as scaffolding in construction in many parts of Asia. Rattan is a vine that grows in the jungles; when rattan is manufactured into furniture, it can be solid.

You can find out more by reading What Is Stronger Rattan Or Bamboo? by clicking here.

What Is The Eco-Friendly Seagrass Materials Used in Home Decor Products?

Seagrass is exactly as the name implies, a grass that grows in the sea or in areas that have saltwater. As Vietnam has access to a lot of tropical oceans, seagrass is abundant in Vietnam. A lot of the seagrass used for manufacturing home decor products is farmed to be cut and processed specifically for seagrass weaving. This seagrass is cut, dried, spun, dyed, and then woven into many different items, including baskets, lampshades, furniture, and area rugs. But seagrass also has some great eco-friendly properties that make it a great alternative to plastic.

By clicking here, you can find out more by reading our blog Eco-Friendly Seagrass Materials Used in Home Decor Products.