To start manufacturing or making pottery, you may want to know if you can glaze or fire pottery without a kiln.

Glazed pottery, stoneware, ceramics, and porcelain must be fired at high temperatures. You need to have a kiln to fire them at these high temperatures. There are several kilns, but the main kilns are electrical kilns, fuel-burning kilns, and gas kilns.

All Glazed Pottery Should Be Fired In A Kiln

For glazed pottery such as stoneware, ceramic, or porcelain to become pottery, they must be fired at high temperatures. Most clays must be fired in the 1,000 C to 2,000 F range; this is an extremely high-temperature rate.

Without a kiln, you really cannot fire the pottery this hot. A kiln is designed to be able to fire pottery at these scorching temperatures safely.

The kilns have chambers designed to fire clay at very high temperatures safely. You can not safely fire pottery without using a kiln.

Types Of Kiln For Firing Pottery

Factories or individuals firing clay usually have an electrical, fuel-burning, or gas kiln. The principle of all kilns is the same; the kiln’s purpose is to fire the pottery at very high temperatures safely.

Most kilns have a metal outer layer or structure and an inner insulating barrier. This barrier ensures that the kiln is safe and that not so much heat is felt on the outside layers. There can be some differences between an electrical and gas kiln.

Here is some basic information about the gas, fuel burning, and electrical kiln:

About Electrical Pottery Kilns

Most people firing pottery as a hobby or in a small workshop will use an electric kiln as an electrical kiln is more accessible than a gas kiln.

Modern electrical kilns are also relatively easy to use. The kilns have digital controls that will even allow you to program your firing schedule. Some electrical kilns called Kiln Sitters do not have digital control as they rely on a mechanical device to switch off the kiln when it reaches a specific temperature; the kiln sitters are considered semi-automatic kilns.

Here are a few things which are essential for an electrical kiln:

- A firing schedule is like a timetable or schedule; the kiln will increase in temperature at a specific rate.

- The firing of the kiln has specific segments, and some segments of the firing process will heat up faster than others.

- Electric kilns can come in a variety of sizes. Some are very small and can be used to make jewelry or test color tiles. Others are very large that can do production runs.

- Elements heat electrical kilns. Depending on the size of the kiln, the kiln can have one or many elements to heat the kiln.

- When the kiln is heated, the hot air will rise to the top, and cooler air will be at the bottom. The cooler air will also get hot as the kiln continues to heat. Because of this, for large kilns, it can be essential to what pottery is put near the top, bottom, or sides.

- Most electric kilns have a maximum firing temperature they can heat up to; some electric kilns can reach up to 2012 F or 1100 C, which is not hot enough for high-fired porcelain. That is why many electrical kilns fire mainly earthenware or bisque. So if you want to do high-fired porcelain, you must have a kiln that can fire at high temperatures.

A lot of what will help determine how hot a kiln can get is the design of the kiln and the kind of heating elements used for the kiln.

Coal Or Wood Fuel Burning Kilns

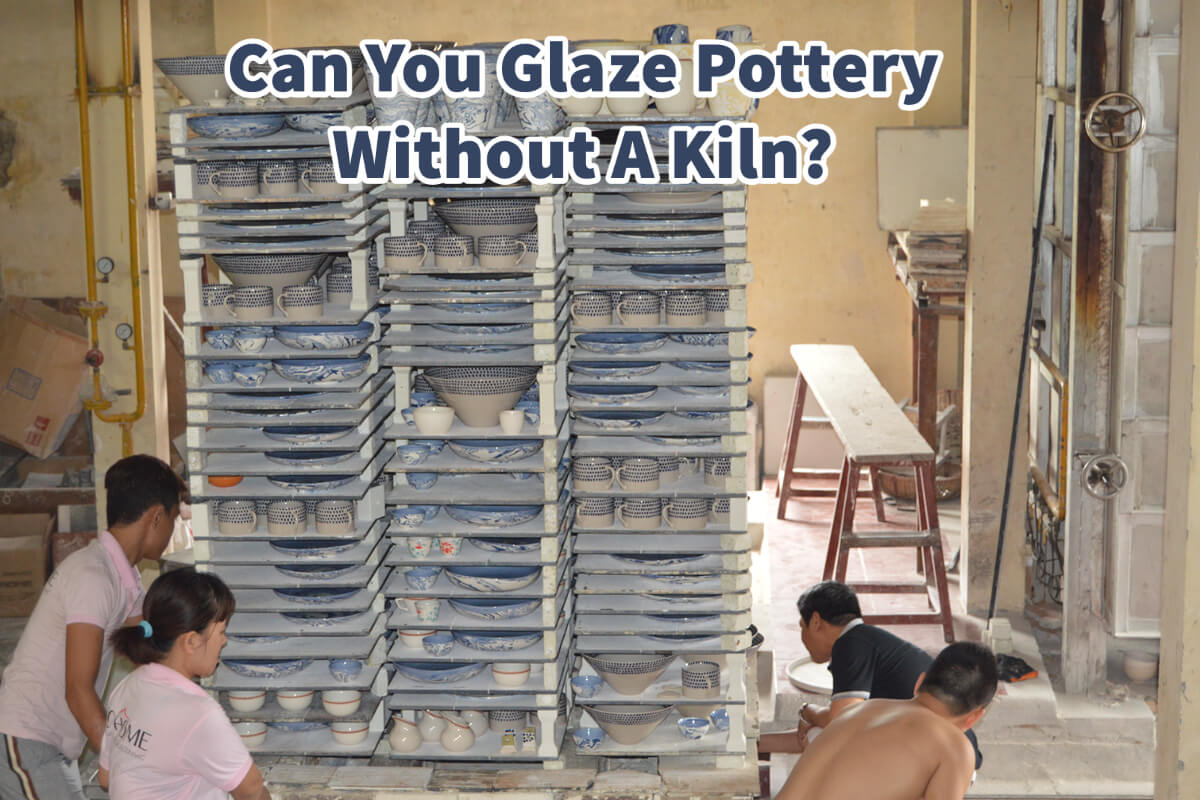

Another kind of kiln that can be used is a fuel-burning kiln. Some factories in Asia may still use fuel-burning kilns.

A fuel-burning kiln is usually a kiln that is heated by burning coal’ I have also seen them heated by wood. Today coal is not considered a clean burning fuel, so many factories using fuel-burning coal have had to change to another type of kiln.

A fuel-burning kiln is usually a large kiln and is only used for large-scale manufacturing. Some fuel-burning kilns are enormous, so you almost walk into a room to load the kiln and then close the door to fire the kiln.

Gas Kilns

Gas kilns are also fuel-burning kinds of kilns. Many of the factories we work with in Asia will use a gas kiln for their production.

Different types of gas can be used to fire up the kiln. Some of the gas used can be natural gas, butane, or propane.

Here are a few things about a gas-burning kiln:

- Gas-burning kilns are heated through a burner port. Depending on the size of the kiln, there can be several burner pots.

- Gas kilns can come in various sizes, but many are enormous as they are used in manufacturing and production.

- An advantage of a gas kiln is its soft flame that can usually be controlled.

- Gas kilns need airflow, so they need a chimney, as a gas kiln needs a draft.

- The draft on the kilns can be controlled using a damper.

Most manufacturers will use a gas kiln as they can heat up to scorching temperatures.

To fire pottery, you need to have a kiln, as the stoneware, ceramics, and porcelain all need to be fired at very high temperatures; to properly fire clay, you need to have a kiln.

Find out more about how Mondoro can help you create, develop, and manufacture excellent home decor and furniture products – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal. You can find it on all major podcast platforms. Try out to listen to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel filled with great videos and information by clicking here.

Related Content

How Does The Firing Temperature Affect Ceramics Production?

If a ceramic piece is not fired at the correct temperature, it will make a huge difference in the final product’s outcome. It is also important that the correct kiln is used for the production process. This is because many things must be considered when using a kiln to fire ceramics. During the firing process, many things can cause the final product to fail or crack.

You can learn more by reading our blog, How Does The Firing Temperature Affect Ceramics Production?, by clicking here.

Can I Put A Clearcoat On Top Of Lacquer Paint?

We spray a PU topcoat on top of our lacquer products. But to correctly spray the PU top coat, you need first to make sure the lacquer is completely dry, then spray a light PU clear coat on top of the paint. We sand in between each coat to ensure no issues with the topcoat layers.

You can read our blog on Can I Put A Clearcoat On Top Of Lacquer Paint? by clicking here.

3-D Porcelain Manufacturing, All You Need to Know

Home decor and home furnishing products in 3-D continue to be an important home decor trend. Many types of home furnishing products use 3-D elements. The 3-D porcelain is a very unique product in that it is using modern-day computerized technology to efficiently produce a variety of 3-D shapes and sizes.

You can learn more by reading our blog, 3-D Porcelain Manufacturing, All You Need to Know, by clicking here.