In our modern society, granite and quartz are extensively used for various residential and commercial applications, notably countertops. The price tags of these materials, which can significantly impact a project’s total cost, are subject to a complex network of factors.

This document aims to guide the reader through the pricing dynamics of the granite and quartz markets, providing an understanding of the processes, regulations, and elements affecting costs. It concludes with a comparative cost analysis of the two materials weighed against color, finish, quality, and beyond factors to determine whether a higher price equates to a better choice.

Table of Contents

- Understanding the Granite Market

- Understanding the Quartz Market

- Comparative Cost Analysis of Quartz and Granite

- Related Content

Understanding the Granite Market

The Influence of Market Forces on Granite Pricing

Imagine watching a fascinating game of chess—the intricate moves, unpredictability, and the subsequent joy of victory or the sorrow of defeat. Virtually identical parallels can be drawn to the marketplace.

Every product or service available succumbs to the subtle and not-so-subtle maneuvers dictated by what we refer to as ‘market forces.’ Today, we delve into how these market forces affect the pricing of one material notoriously known for its aesthetic appeal – granite.

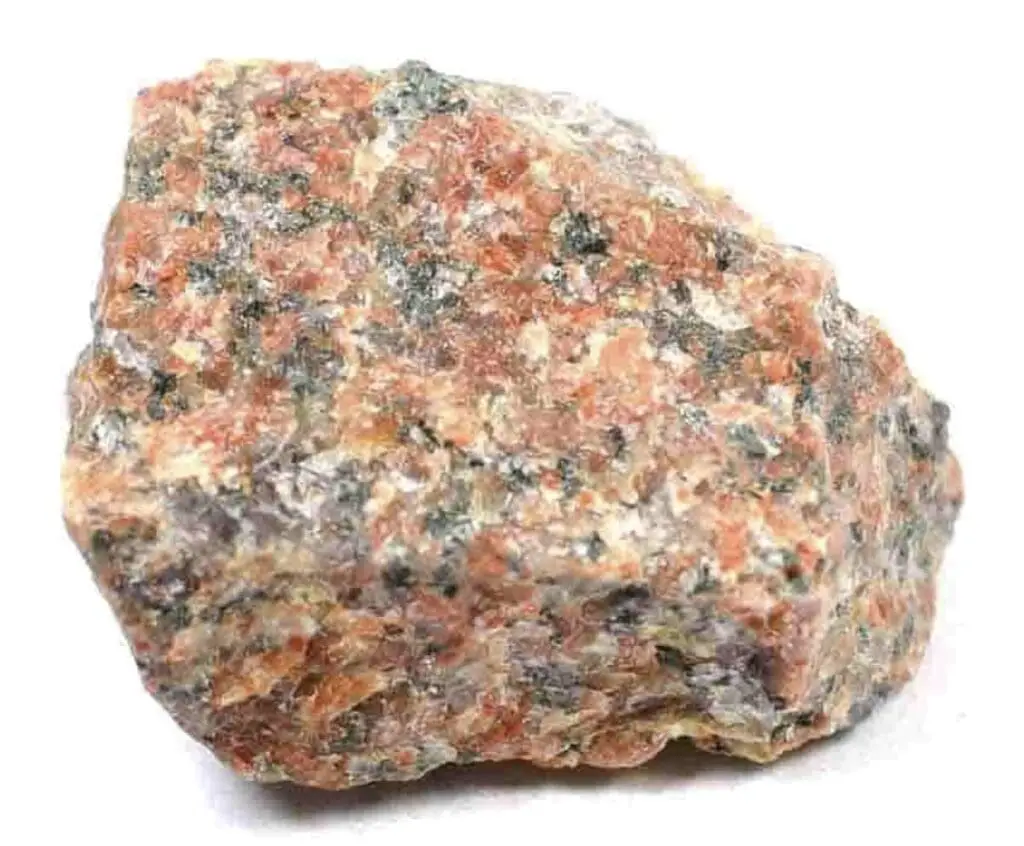

Comprising mainly of quartz, mica, and feldspar, granite is a naturally occurring igneous rock that has become a desired choice in construction and decor. Its popularity spans residential and commercial architecture projects due to its durability and distinct beauty. Nevertheless, the laws of supply and demand, two significant market forces, play vital roles in shaping the pricing structure for granite materials.

In the case of granite, supply is immensely impacted by factors such as raw material availability, mining costs, and logistic expenses. A scarcity of high-quality raw granite, for example, naturally shrinks the pool of available supply, placing upward pressure on prices.

Similarly, a rise in mining costs – labor charges, equipment maintenance, fuel costs – or logistic expenses, like transportation and import duties- equally adds to the cost, thereby skyrocketing the final pricing of granite.

Flip over to the demand side of the equation, and we witness a plethora of factors at play. The desire for granite tends to intensify in booming real estate markets, with homeowners and businesses seeking to capitalize on granite’s aesthetic appeal to increase property value. Climbing demand against a static or reducing supply will predictably bring about a marked surge in granite prices.

Another crucial component of the market forces is competition. Alternative materials such as quartz, marble, or laminathaveas induce a competitive market where each player fights hard to win consumer preference.

The entry or prominence of these alternatives can lead to a downfall in the demand for granite, in turn plugging a downward pressure on its pricing.

Moreover, the ever-evolving governmental policies and regulations on domestic and international platforms add complexity to the mix. Policies straddling environmental sustainability, mining regulations, and import-export rules can influence the availability and cost of gr, unite.

Ultimately, the game of the marketplace is an elaborate set of strategic moves akin to our chess analogy. It takes an expert touch to predict and capitalize effectively on supply-demand influences, competition, and policies.

For granite or any other product or service under the sun, understanding these market forces is indispensable for staying ahead and thriving in the marketplace. And while the granite industry continues to navigate these market currents, buyers and suppliers alike can benefit immensely from staying in the knowhow of these elements of influence.

Understanding the Quartz Market

The Discernible Costs: Delving into the World of Quartz

Let’s look at quartz, a fierce competitor in quality and cost to granite among materials commonly used in construction. The rising popularity of this beautiful and durable material has caused a surge in its demand. But what exactly influences the cost? Let’s unravel the enigma and look deeper into the world of quartz.

Firstly, the defining value of quartz does not stem solely from its raw form but through manufacturing. Unlike granite, quartz is an engineered stone comprising about 90-95% ground quartz mixed with resins, polymers, and pigments.

This transformation process owes a part of quartz’s price tag, contributing directly to its cost. This transformational journey from raw quartz to spiffy quartz countertops entails manufacturing costs and labor expenses in its pricing matrix.

Operational costs, specifically mining, are another key contributor to the price determination. The abundant availability of quartz lures us into thinking that mining costs would be negligible. Even though quartz is the second most abundant mineral on the earth’s crust, extracting this resource is quite sophisticated and labor-intensive; hence, there’s your hike in price.

Another factor to chew on is the influence of transportation. The fact that the quartz is globally distributed means it could be mined from various locations, inevitably leading to additional shipping and handling costs. Sometimes, even more so if it’s procured from remote regions. Therefore, transportation and logistics costs add another layer to the price bubble.

Moreover, we cannot overlook the role of economies of scale in pricing. As production volume increases, costs per unit can decrease. That means manufacturers that produce quartz products on a large scale can offer more competitive prices, as they tend to go easy on your pocket compared to your small-scale producers.

Finally, import taxes, duties, and regulations also play a pivotal role in influencing quartz prices. With the bulk of quartz countertops produced in countries like China and India, import duties and other trade regulations often lead to changes in the final pricing for buyers in the U.S.

Hence, understanding these determinants will aid buyers and suppliers in making sound decisions to optimize cost and profitability in the quartz industry. Through continual innovation, robust networking, and keeping an eye on business opportunities, industry players can navigate the choppy waters of the quartz industry in a savvy fashion.

As such, the fascinating world of quartz and its pricing dynamics beckons an arena rife with potential for entrepreneurial minds to explore, innovate, and prosper.

Comparative Cost Analysis of Quartz and Granite

Manufacturing Quartz: A Costly Process

While granite has undisputed popularity, quartz has unique charm and qualities. However, the beauty of quartz doesn’t come cheap. One key driver of its price is the complex manufacturing process involved.

Unlike granite, which is mined and cut into slabs, quartz is engineered. This means that ground quartz is combined with resins, polymers, and pigments to create a product that is over 90% natural stone. This involved process often results in higher prices compared to granite.

Labor and Operational Costs

The production of quartz is labor-intensive, which directly influences its price. Since quartz is manufactured chiefly rather than directly sourced from mining like granite, it requires more human labor. With staffing, wages, benefits, and training expenditures to consider, these labor costs add to the final pricing of quartz countertops.

Transportation and Handling Costs

Another significant factor contributing to quartz’s higher cost is the transportation and handling expense. Quartz, especially the high-end variations, are typically imported from overseas countries. The shipping, packaging, handling, and distribution fees add to quartz countertops’ wholesale and retail prices.

Economies of Scale

Running a quartz-manufacturing facility efficiently requires significant capital investment. As such, there’s an inherent advantage for larger, more established companies that can realize economies of scale.

This means they can consistently produce large volumes of quartz countertops and lower per-unit costs. However, given quartz products’ premium positioning and branding, these savings may not always be passed onto the end customer.

Taxes, Duties, and Regulations

Since many high-end quartz products are manufactured overseas and imported into the United States, they’re often subject to import taxes, duties, and other tariffs. These levies inevitably trickle down to the retail cost, making quartz more expensive than its locally sourced counterparts like granite.

Achieving Cost-Efficiency in Quartz Industry

Optimizing costs while maximizing profits is an ongoing challenge for businesses operating within the quartz industry. Some strategies may include streamlining operations, adopting energy-efficient machinery, leveraging bulk purchasing with suppliers, navigating international trade policies, and implementing innovative warehousing and logistics solutions.

While quartz tends to be more expensive than granite, its incredible durability, unique aesthetics, and low-maintenance attributes still make it a market favorite. Understanding the components that contribute to its higher cost gives consumers a clear perspective and businesses a roadmap to improve profitability.

Understanding the intricacies of the granite and quartz market illuminates the complex factors affecting their prices. Elements such as import-export regulations, quarry operations, supply and demand, transportation, production costs, and technological progress can drastically adjust these prices.

Furthermore, there’s more to selecting these materials than cost alone – durability, aesthetics, and maintenance all have essential roles. Ultimately, the personal preferences and needs of the buyer become the final determinants in the granite versus quartz debate rather than cost alone.

Find out more about how Mondoro can help you create, develop, and manufacture excellent home decor and home furniture products – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal. You can find it on all major podcast platforms. Try out to listen to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel filled with great videos and information by clicking here.

Related Content

Why Is It Called Mother Of Pearl? Pearls and Mother of Pearls

The name mother used in Mother of Pearl is thought to come from a nearly obsolete meaning of mother, which means “scrum, drugs, or leftover fifth.” This would be because the Mother of Pearl comes from the leftover shell of the oyster, clam, or mussel. The scientific name for Mother of Pearl is nacre.

You can discover more by reading Why Is It Called Mother Of Pearl? Pearls and Mother of Pearls by clicking here.

What is the Mother of Pearl Shell Used in Home Decor Products?

Mother of pearl, which is also known by the scientific name of nacre, is a pearl layer on the inner layer of the oyster shell. This pearl layer of the oyster is taken off the outer oyster shell. Then the leftover inner pearl shell is then cut into various small shapes and sizes to be then glued to various home decors products such as mirrors, boxes, trays, and lamp bases.

You can discover more by reading What is the Mother of Pearl Shell Used in Home Decor Products?by clicking here.

How To Identify If Mother Of Pearl Is Real? Spotting What’s Fake

When considering a Mother of Pearl for home decor and home furnishing products, you need to ensure that the mother of pearl you were getting is the highest quality real Mother of Pearl. You can do some basic tests to help you ensure that the Mother of Pearl you are purchasing is a natural material and not the fake versions of mother of pearl.

You can discover more by reading How To Identify If Mother Of Pearl Is Real? Spotting What’s Fake by clicking here.