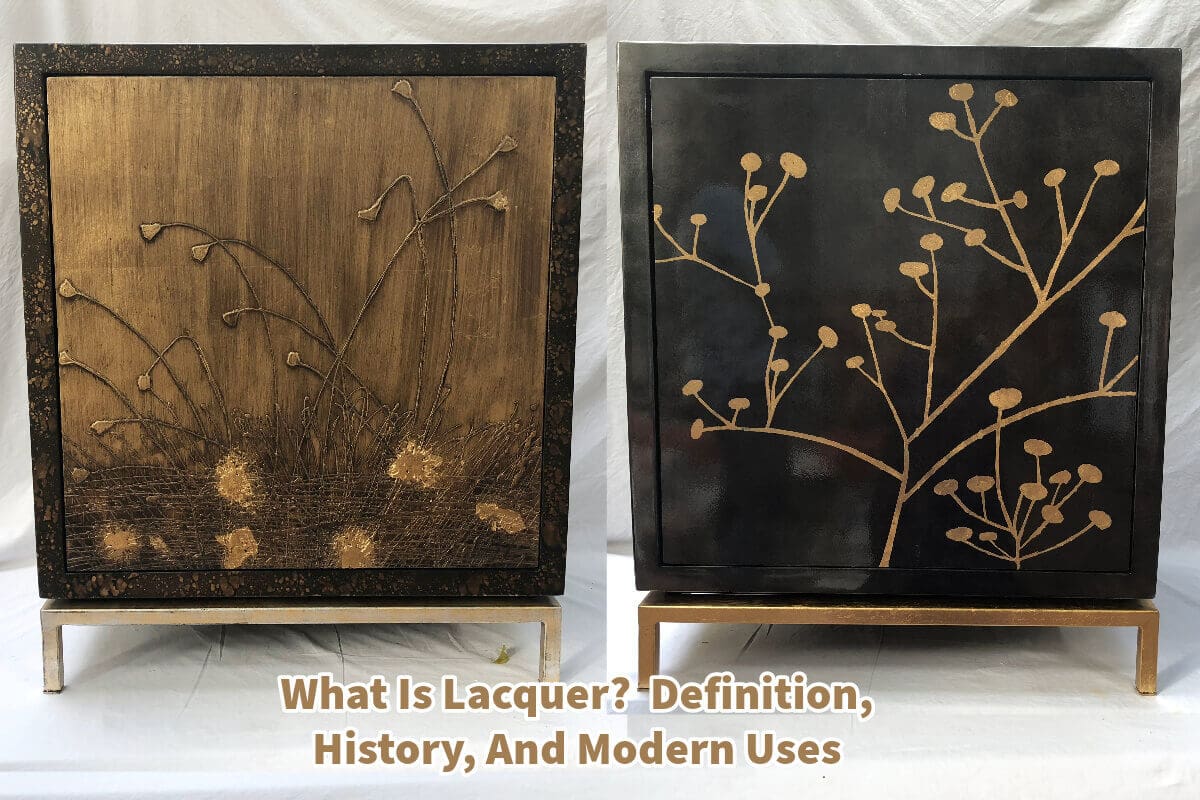

Lacquer is distinguished in home decor and furniture making, where it is synonymous with a sleek, lustrous finish that enhances the visual appeal of various items.

From the polished surfaces of modern home furnishings to the delicate sheen on musical instruments and the vibrant finish on classic automobiles, lacquer represents a timeless quality that melds beauty with durability. As a finish, it has adeptly evolved, incorporating advancements in material science while preserving the foundational properties that have made it a mainstay in aesthetics and craftsmanship.

Table of Contents

- What Is Lacquer? An Exploration Of Its Definition, History, And Modern Uses

- Historical Perspective Of Lacquer

- Environmental Concerns And The Shift To Water-Based Lacquers

- Modern Applications Of Lacquer

- Related Content

What Is Lacquer? An Exploration Of Its Definition, History, And Modern Uses

Lacquer is a term that resonates with a particular gloss and sophistication, conjuring images of smooth, shining surfaces on furniture, musical instruments, and cars. It’s a finish that has stood the test of time, evolving with technology while retaining its essential characteristics.

Read on as we strive to define lacquer, trace its historical roots, and discuss its evolution into the finish we know and use today.

Defining Lacquer

At its most basic, lacquer is a complex, shiny finish applied to materials such as wood or metal. Traditionally, it is derived from the sap of the lacquer tree, native to Asia, which contains a resin that forms a hard, protective coating when exposed to air.

Over time, the definition of lacquer has expanded to include synthetic substances that mimic these qualities.

The essence of lacquer lies in its ability to provide a protective layer that enhances the aesthetic appeal of the object it covers.

The unique combination of a visually appealing gloss and a barrier against wear and environmental damage has made lacquer a lasting favorite in various industries.

Historical Perspective Of Lacquer

Lacquer’s history is as rich and layered as the finish itself. The use of natural lacquer can be traced back thousands of years in Asia, particularly China and Japan, where artisans perfected the art of lacquering objects.

In these cultures, lacquer was more than just a protective coating; it was a medium for artistic expression, often inlaid with gold, silver, and intricate designs.

The turning point for lacquer came in the 1920s when it gained favor over shellac as a finish for its superior protection and wear resistance. Shellac, made from the secretions of the lac bug, was famous for its natural origin and ease of application, but it couldn’t match the lacquer’s durability.

Nitrocellulose Lacquer

The advent of nitrocellulose, or NC lacquer, marked a significant advancement. This type of lacquer consists of cellulosic solids derived from cotton, chemically modified with nitric acid, and suspended in a solvent.

Once dried, its formulation allowed each layer to dissolve slightly into the previous one upon application, creating a single, unified, and robust layer. This feature made NC lacquer particularly suitable for applications requiring a challenging yet flexible and repairable finish.

NC lacquer quickly became a staple in various industries, particularly automotive manufacturing, where its ability to impart a durable shine on vehicles was highly prized. The furniture industry also embraced nitrocellulose lacquer for its fast drying time and substantial protection against scratches and spills.

Environmental Concerns And The Shift To Water-Based Lacquers

As with many solvent-based finishes, NC lacquer’s widespread use raised environmental concerns, primarily due to its solvents’ volatile organic compounds (VOCs). These VOCs contribute to air pollution and can have harmful health effects.

In response to these concerns, manufacturers have developed water-based lacquer formulations. These newer lacquers aim to match the performance characteristics of nitrocellulosic formulas while reducing the environmental impact.

Water-based lacquers offer lower VOC emissions, easier cleanup, and less odor, making them more user- and environmentally friendly.

However, transitioning from traditional NC lacquer to water-based alternatives is challenging. Differences in application, drying time, and final finish must be considered. Professionals and hobbyists must adapt their techniques to achieve the same high-quality results they are accustomed to with nitrocellulose lacquer.

Modern Applications Of Lacquer

Today, lacquer remains a preferred finish in various applications. In the automotive industry, it ensures that vehicles not only gleam with a high-gloss finish but are also shielded from the elements and the wear and tear of the road.

In musical instruments, lacquer helps protect delicate wood while enhancing sound quality through its unique acoustic properties. For furniture, lacquer provides an elegant and durable finish that can withstand daily use.

Despite advancements and alternatives, the appeal of lacquer—whether based on natural resin, nitrocellulose, or modern water-based formulations—remains unchanged. It offers unparalleled beauty and protection, preserving the value and integrity of the objects it adorns.

Lacquer has adapted to the times while maintaining the characteristics that made it a cornerstone finish in various trades. Its evolution from natural resins to synthetic formulations reflects our changing world’s demands for sustainability and environmental responsibility without compromising quality and performance.

Lacquer’s storied past and its continued relevance today testify to its enduring appeal and functionality as a finish.

If you are looking for any lacquer products to manufacture in Asia, Mondoro would love to help you.

Find out more about how Mondoro can help you create, develop, and manufacture excellent home decor and furniture products – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal. You can find it on all major podcast platforms. Try out listening to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel with great videos and information by clicking here.

Related Content

What Is Stronger Rattan Or Bamboo?

Bamboo is more robust than rattan. Some bamboo is known even to have a higher tensile strength than steel; this is why bamboo is used as scaffolding in construction in many parts of Asia. Rattan is a vine that grows in the jungles; when rattan is manufactured into furniture, it can be solid.

You can learn more by reading our blog, What Is Stronger Rattan Or Bamboo? by clicking here.

How Do You Make A Bamboo Lamp Shade? All About Bamboo Lampshades

To manufacture or make bamboo lampshades, you need to 1) properly prepare the bamboo materials, 2) build a metal frame, 3) wrap the metal frame, 4) secure the bamboo onto the metal frame, 5) spray color on top of the bamboo shade if you desire the lampshade to be a color other than natural and 6) spray a top coat on the entire shade to protect the bamboo shade’s finish.

You can read our blog about How Do You Make A Bamboo Lamp Shade? All About Bamboo Lampshades by clicking here.

Rattan Vs. Bamboo – The Differences Between The Materials Explained

Rattan and bamboo are not the same material, as they have different characteristics and uses. For example, bamboo is hollow and grows straight as a tree would. Rattan is a solid material that is easily bent and grows in rainforests as a vine.

You can learn more by reading our blog, Rattan Vs. Bamboo – The Differences Between the Materials Explained, by clicking here.