In the world of high-stakes project management and intricate supply chains, there is a universal truth often summarized by the management adage: “You cannot manage what you cannot measure.”

Whether you are developing software, constructing a skyscraper, or, as we will explore today, crafting a piece of ultra-luxury furniture, the difference between a chaotic failure and a profitable masterpiece usually comes down to visibility. How clearly can you see the progress of your project? How quickly do you know when something has gone wrong?

Table of Contents

- Why Should You Look at KPIs for Home Decor and Home Furniture Manufacturing?

- The Framework: The “Triple Constraint” in Luxury Goods

- Case Study: The High-End Dining Table KPI Tracker

- Deep Dive Podcast

- Related Content

Why Should You Look at KPIs for Home Decor and Home Furniture Manufacturing?

For artisans and designers, the business side of creation—spreadsheets, timelines, and budgets—often feels antithetical to the creative process. There is a fear that introducing rigid metrics will stifle artistry. However, the opposite is true. When applied correctly, robust tracking mechanisms free creators to focus on their craft by ensuring the logistical foundation beneath them is solid.

This “navigational system” for business is built on KPIs—Key Performance Indicators. In this post, we will demystify what KPIs are, explain how they fit into the fundamental “Triple Constraint” of project management, and take a deep dive into a real-world example: tracking the production of a custom, high-end dining table featuring specialized lacquer and gold leaf finishes.

What Are KPIs (and What Are They Not)?

Before we get to the sawdust and gold leaf, we must establish a baseline definition.

A Key Performance Indicator (KPI) is a quantifiable measure used to evaluate the success of an organization, employee, or project in meeting objectives for performance.

Think of your business or project like a high-performance sports car. You have a dashboard full of dials and gauges. Some tell you your speed, others your fuel level, engine temperature, or RPM.

- Metrics are all the data points the car produces. The tire pressure, the exact interior temperature, the radio station volume—these are all metrics. They are data, but they might not be crucial right this second.

- KPIs are the specific gauges you must watch to ensure you finish the race without blowing up the engine. If your goal is to win a long-distance race, your fuel gauge is a KPI. If your goal is a drag race, your RPM gauge is a critical KPI.

Why KPIs Matter

In the context of supply chain and project management, KPIs serve three primary functions:

- A “North Star” for Navigation: Projects easily get sidetracked by daily fires. KPIs remind the entire team—from the project manager to the artisan on the shop floor—what “success” actually looks like.

- Early Warning Systems: A good KPI turns red before the project fails. It allows project managers to be proactive rather than reactive. If a KPI shows that raw material usage is trending up, you can fix the cutting process before you run out of expensive wood.

- Objective Communication: Stakeholders (clients, investors, bosses) want to know how things are going. Saying “It’s going great, the table looks beautiful” is subjective. Saying “We are tracking at a 1.1 Schedule Performance Index with a 98% First Pass Quality Yield” is objective, professional proof of progress.

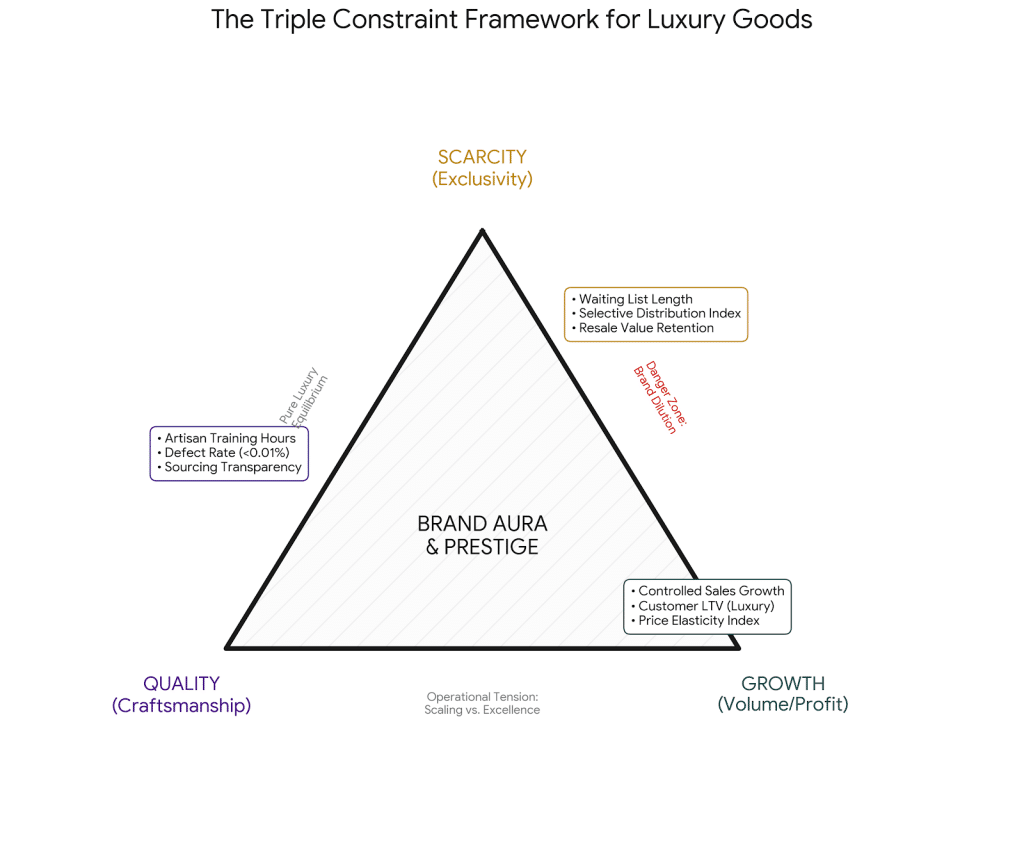

The Framework: The “Triple Constraint” in Luxury Goods

To understand which KPIs to choose, you must understand what you are trying to control. In formal project management, this is governed by the “Triple Constraint,” often visualized as a triangle.

The three corners are:

- Scope: What are we building? (The deliverables, features, and quality standards).

- Schedule: How much time do we have?

- Budget: How much money can we spend?

The rule of the triangle is unyielding: You cannot change one side without impacting at least one of the others.

If you want to increase the Scope (add more intricate gold leaf patterns to the table), you must either increase the Budget (to pay for more labor/materials) or extend the Schedule (it will take longer).

If the client demands the table sooner (shrinking the Schedule), you must either increase the Budget (pay overtime) or reduce the Scope (cut corners on quality).

The Luxury Challenge

In high-end furniture production, the “Triple Constraint” is exceptionally difficult to manage because the Scope corner is virtually immovable.

When a client commissions a custom dining table with specialized lacquer and gold leaf finishes, they are buying perfection.

You cannot reduce the quality of the lacquer to save money. You cannot rush the drying process to meet a schedule. In luxury goods, quality (Scope) is non-negotiable.

Therefore, the KPIs used to manage such a project must be hyper-focused on protecting that quality while ruthlessly managing the other two constraints—schedule and budget—so the project remains profitable.

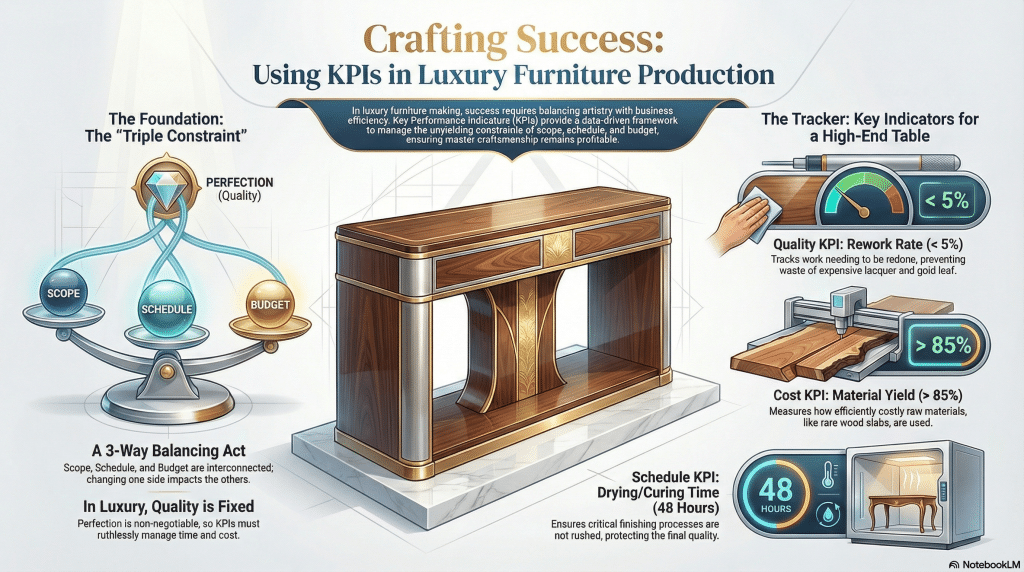

Case Study: The High-End Dining Table KPI Tracker

Let us apply this theory to the real world. Imagine you are managing the production of a bespoke dining table. This is not flat-pack furniture. It involves rare imported wood slabs, multiple layers of hand-applied lacquer that require a dust-free environment, and delicate gold leaf accents applied by a master gilder.

To manage this effectively, you need a tracker that balances artistry with efficiency.

Below is an example of a KPI tracker designed specifically for this type of high-stakes project. We will break down each component.

| Category | KPI Name | Target | Why it matters |

| Quality | Rework Rate | < 5% | Tracks how many pieces require sanding/refinishing due to lacquer bubbles or gold leaf peeling. |

| Cost | Material Yield | > 85% | Measures how efficiently you use expensive raw materials (e.g., rare wood slabs or minerals). |

| Schedule | Drying/Curing Time | 48 Hours | Ensures you don’t rush the finish, which would compromise the “Scope” (quality). |

| Budget | Actual vs. Budgeted Cost | +/- 2% | Tracks if the cost of specialized labor or rare materials is staying within your initial quote. |

| Agile | Cycle Time per Phase | 3 Days | How long it takes to move from the “Design/Pattern” phase to the “Material Preparation” phase. |

Deep Dive into the Indicators

Let’s analyze why these specific KPIs were chosen and what they tell the project manager.

1. Quality KPI: Rework Rate (Target: < 5%)

What it is: This measures the percentage of work that fails quality control the first time and must be redone. In our example, if you apply lacquer to 100 table legs, and 5 of them have bubbles and need to be sanded down and resprayed, your rework rate is 5%.

Why it is critical for this project: In high-gloss lacquer and gold leaf work, rework is devastatingly expensive. You don’t just lose the time it takes to redo it; you lose the expensive materials you have to sand off, and you risk damaging the substrate wood beneath.

A high rework rate is a massive red flag. It suggests a systemic problem: is the humidity in the spray booth too high? Is the gilder rushing their work? Is the raw wood not being prepped correctly? Tracking this KPI allows you to identify and fix the root cause before it destroys your profit margin.

2. Cost KPI: Material Yield (Target: > 85%)

What it is: This is a classic Supply Chain KPI. It measures how much of the raw material you purchased actually ends up in the final product versus ending up as scrap on the floor.

Why it is critical for this project: When dealing with standard pine, a little waste is acceptable. When dealing with rare, imported walnut slabs costing thousands of dollars, or 24k gold leaf sheets, every scrap matters.

If your target is >85% and your KPI shows you are currently at 70%, you are bleeding money. It means your cutting patterns are inefficient, or perhaps artisans are being careless with the gold leaf application. This KPI forces the team to maximize the value of every inch of raw material.

3. Schedule KPI: Drying/Curing Time (Target: 48 Hours)

What it is: This tracks the actual time a piece spends sitting idle between processes to allow finishes to set chemically.

Why it is critical for this project: This is a fascinating KPI because it acts as a “governor” on speed. Usually, schedule KPIs try to make things go faster. Here, the KPI ensures you slow down.

High-quality lacquer requires precise curing times between coats to achieve depth and durability. If a project manager sees this KPI dropping—say, pieces are moving in 24 hours instead of 48—it is an immediate alarm. It means someone is rushing the process, endangering the “Scope” (quality) corner of the Triple Constraint. This KPI protects the integrity of the craft.

4. Budget KPI: Actual vs. Budgeted Cost (Target: +/- 2%)

What it is: The quintessential project management metric. It compares what you thought you would spend at this point in the project versus what you have actually spent.

Why it is critical for this project: Custom projects are notorious for “scope creep” and hidden costs. Did the rare wood cost 10% more to ship than anticipated? Did the gilder take 50 hours instead of the estimated 40?

A target of +/- 2% is very tight, reflecting the high stakes of luxury goods. There is very little room for error in the pricing model. If this KPI starts drifting toward +5% or +10%, the project manager needs to immediately intervene, perhaps by renegotiating with suppliers or finding efficiencies in labor elsewhere, to ensure the project doesn’t end up costing the company money to build.

5. Agile KPI: Cycle Time per Phase (Target: 3 Days)

What it is: Borrowed from Agile and Lean methodologies, this measures the time it takes for a unit of work to pass completely through one distinct phase of production.

Why it is critical for this project: Even traditional crafts have distinct phases: Design, Material Prep, Assembly, Finishing, Curing, Final Inspection.

If the “Design/Pattern” phase is supposed to take 3 days, but the KPI shows it is averaging 7 days, you have a bottleneck before production even begins. Perhaps the client approval process is too slow, or the CAD designers are overloaded. By tracking cycle time, you can pinpoint exactly where in the pipeline things are getting stuck, rather than just knowing the whole project is “late.”

Data in Service of Art

When looking at a finished, gleaming dining table with flawless gold accents, few people think about spreadsheets. Yet, that perfection is only reproducible and profitable if the underlying processes are sound.

The KPI tracker above is not meant to turn artisans into robots. It is designed to provide a transparent framework that highlights issues early.

By using KPIs to balance the “Triple Constraint,” you ensure that budgets aren’t blown on wasted gold leaf, schedules aren’t derailed by rework, and most importantly, the scope—that uncompromising commitment to luxury quality—is never sacrificed.

Deep Dive Podcast

Check out our Deep Dive Podcast.

Find out more about how Mondoro can help you create, develop, and manufacture excellent home decor and furniture products – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal and Deep Dive by Global Trade Gal. You can find it on all major podcast platforms. Try out listening to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel with great videos and information by clicking here.

Related Content

Pantone’s Color of the Year: Cloud Dancer – A Breath of Fresh Air for 2026

In true Pantone fashion, they surprised us all with a choice that goes beyond expectations: Cloud Dancer. This serene, versatile shade has captured my heart, and I believe it perfectly encapsulates the emotions, aspirations, and mindset of 2026.

Read our blog Pantone’s Color of the Year: Cloud Dancer – A Breath of Fresh Air for 2026 by clicking here.

Using Shapr3D and Google Gemini: A Powerful Design Duo

Read on as we will explore how I use Shapr3D, a cutting-edge CAD program, alongside Google Gemini, an AI-powered visualization tool, to enhance my design process. These tools are not just software—they’re design companions that help me bring my creative visions to life in ways that were previously unimaginable.

Read our blog Using Shapr3D and Google Gemini: A Powerful Design Duo by clicking here.

Why AI is the New Design Companion

Design is a deeply personal and creative process, driven by human imagination and ingenuity. At its core, design is about expressing ideas, solving problems, and creating something that resonates with others. But as the world evolves, so do the tools we use to bring our ideas to life. Enter artificial intelligence (AI), a technology that, when used correctly, can become one of the most valuable companions for designers, product developers, and creatives alike.

Read our blog Why AI is the New Design Companion by clicking here.