Engineered wood veneer is a revolutionary material that has gained immense popularity in the world of interior design, furniture manufacturing, and construction. Combining the natural beauty of hardwood with enhanced durability, stability, and cost-effectiveness, engineered wood veneer offers a perfect balance between form and function. Whether you’re designing a modern office space, crafting custom furniture, or renovating your home, this versatile material provides a sustainable and aesthetically pleasing solution.

In this comprehensive blog post, we will explore everything you need to know about engineered wood veneer, including its composition, manufacturing process, benefits, applications, and considerations. By the end, you’ll understand why this material has become a go-to choice for architects, designers, and homeowners alike.

Table of Contents

- What Is Engineered Wood Veneer?

- How Is Engineered Wood Veneer Made?

- Key Features and Benefits of Engineered Wood Veneer

- Applications of Engineered Wood Veneer

- Maintenance Tips for Engineered Wood Veneer

- Considerations When Using Engineered Wood Veneer

- Why Choose Engineered Wood Veneer?

- Deep Dive Podcast

- Related Content

What Is Engineered Wood Veneer?

Engineered wood veneer is a real wood product that consists of a thin top layer of genuine hardwood (known as the veneer or “wear layer”) bonded to a core made from other engineered wood materials, such as plywood, high-density fiberboard (HDF), or particle board.

This layered construction creates a highly stable and durable material that mimics the appearance of solid wood while offering several practical advantages.

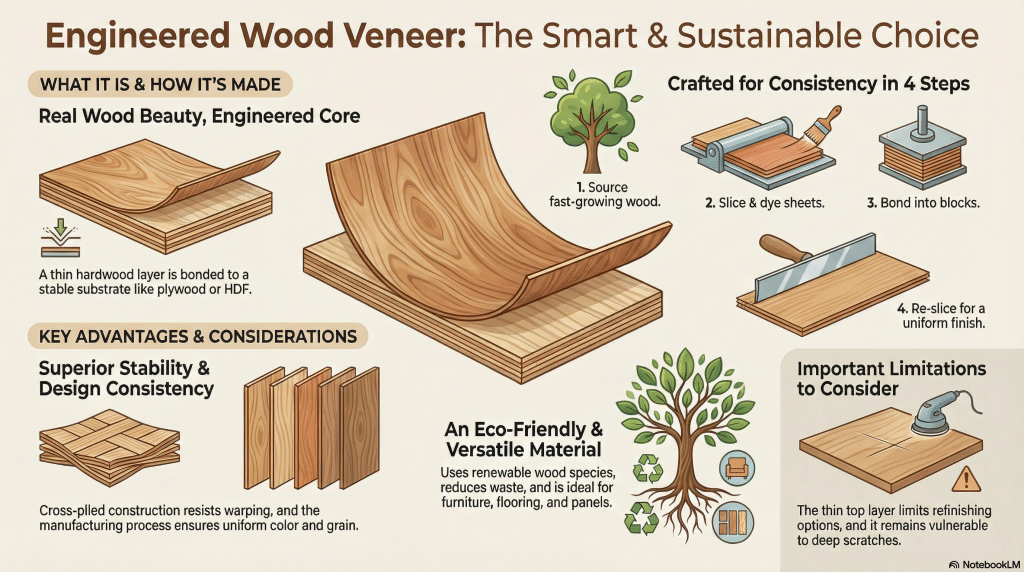

One of the standout features of engineered wood veneer is its cross-plied construction. The grain of the underlying layers is oriented in different directions, which enhances the material’s resistance to expansion, contraction, and warping caused by changes in temperature and humidity.

This makes it an excellent choice for environments where solid wood might not perform as well.

How Is Engineered Wood Veneer Made?

The manufacturing process of engineered wood veneer is a fascinating blend of traditional craftsmanship and modern technology. Here’s a step-by-step breakdown of how this innovative material is created:

1. Sourcing

The process begins with the selection of raw materials. Fast-growing, renewable tree species like poplar, obeche, or eucalyptus are typically used to create engineered veneer.

These species are chosen for their sustainability and ease of processing, making the production process more environmentally friendly.

2. Slicing and Dyeing

The harvested logs are thinly sliced into sheets of veneer, which are then dyed to achieve specific colors and tones. This dyeing process allows manufacturers to replicate the appearance of exotic hardwoods or create custom designs that are consistent across large batches.

3. Bonding

The dyed veneer sheets are glued together into large blocks using adhesives and high-pressure bonding techniques. The orientation of the layers is carefully controlled to create the desired grain patterns and to enhance the material’s structural stability.

4. Re-slicing

The bonded blocks are re-sliced into thin sheets using templates and molds. This step is where the engineered veneer takes on its final appearance, with consistent, pre-designed grain patterns that can mimic natural wood species or create unique, uniform designs.

5. Finishing

The re-sliced veneer sheets are sanded, finished, and prepared for use in various applications. They may be laminated onto cores of plywood, HDF, or particle board to create the final engineered wood veneer product.

Key Features and Benefits of Engineered Wood Veneer

Engineered wood veneer offers a host of advantages that make it a superior alternative to solid wood in many cases. Let’s take a closer look at its key features and benefits:

1. Design Consistency

One of the biggest challenges with natural wood is its inherent variability. Each log has its own unique color, grain pattern, and texture, which can make it difficult to achieve uniformity in large-scale projects.

Depending on the engineered wood veneer design, the engineered wood can help solves this problem by offering a more consistent color and grain patterns across large surface areas.

Even with its design consistency, engineered wood veneer will not be as perfectly uniform as some other manufactured products. This is because it is still made from natural wood, and the grain patterns and texture will ultimately depend on the specific characteristics of the wood used in its production.

2. Durability and Stability

Thanks to its layered construction, engineered wood veneer is significantly more resistant to warping, shrinking, and cracking than solid wood. The cross-plied layers counteract the natural movement of wood, ensuring that the material remains stable even in environments with fluctuating temperature and humidity levels.

3. Eco-Friendliness

Engineered wood veneer is an environmentally conscious choice for several reasons:

- It utilizes fast-growing, renewable tree species, reducing the demand for slow-growing hardwoods.

- The manufacturing process makes efficient use of wood resources, often incorporating sawmill waste and smaller logs that might otherwise go unused.

- By mimicking the appearance of exotic hardwoods, engineered veneer helps reduce the need for logging rare and endangered tree species.

4. Versatility

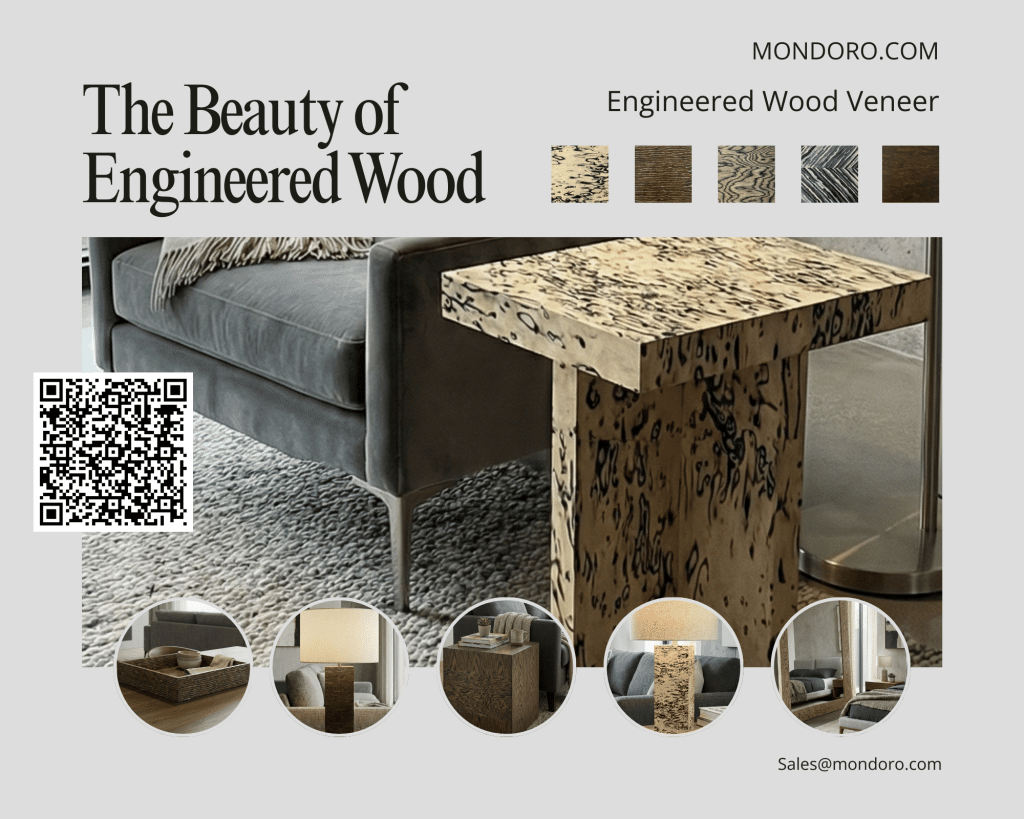

Engineered wood veneer can be used in a wide variety of applications, including:

- Furniture (tables, chairs, cabinets, etc.)

- Decorative accents – boxes, trays, lamps and other home decor products.

Its versatility makes it a popular choice for both residential and commercial projects. - Flooring

- Wall paneling

- Doors

Its versatility makes it a popular choice for both residential and commercial projects.

5. Light Refraction and Aesthetic Appeal

One unique characteristic of engineered wood veneer is its interaction with light. Depending on the color and finish of the veneer, the way light refracts off the surface can vary significantly.

For example, darker veneers may absorb light and create a rich, warm ambiance, while lighter veneers can reflect light and brighten up a space. The appearance of the veneer can also change subtly under different lighting conditions, adding depth and character to your design.

Applications of Engineered Wood Veneer

Engineered wood veneer is a highly adaptable material that can be used in a wide range of applications. Here are some of the most common uses:

1. Furniture

From sleek modern designs to timeless classics, engineered wood veneer is widely used in furniture manufacturing. Its consistent appearance and durability make it an excellent choice for items like end tables, coffee tables, sofa tables, dining tables, office desks, wardrobes, and cabinets. Basically any kind of furniture.

2. Home Decor

Engineered wood veneer is a versatile material that can be beautifully incorporated into home decor items such as lamp bases, boxes, trays, and more. It offers a stunning way to showcase the elegance and charm of engineered wood in decorative products for the home.

3. Flooring

Engineered wood veneer flooring combines the beauty of hardwood with the practicality of engineered materials. It is more resistant to moisture and temperature changes than solid wood flooring, making it suitable for areas like kitchens and basements.

4. Wall Paneling

For a sophisticated and elegant look, engineered wood veneer can be used as wall paneling. Its uniform grain patterns and rich colors add warmth and character to any space, whether it’s a home, office, or hotel lobby.

5. Doors

Engineered wood veneer is commonly used in the production of interior and exterior doors. Its stability and resistance to warping make it a reliable choice for door construction, while its natural wood appearance enhances the overall aesthetic.

Maintenance Tips for Engineered Wood Veneer

Maintaining engineered wood veneer is similar to maintaining natural wood veneer. Proper care and attention can help preserve its appearance and extend its lifespan. Here are some key maintenance tips:

Cleaning:

Use a soft, damp cloth to wipe down the surface regularly. Avoid using harsh chemicals or abrasive cleaners, as these can damage the finish.

Avoid Excess Moisture:

While engineered wood veneer is more moisture-resistant than solid wood, prolonged exposure to water can still cause damage. Clean up spills immediately and avoid placing the material in areas with high humidity or standing water.

Prevent Scratches:

Protect the surface by using coasters, placemats, and furniture pads. Avoid dragging heavy objects across the veneer, as this can cause scratches or dents. This material is similar to regular wood veneer and is treated in much the same way as traditional wood veneer.

Dusting:

Regular dusting with a microfiber cloth can help maintain the veneer’s natural luster and prevent dirt buildup.

Avoid Direct Sunlight:

Prolonged exposure to direct sunlight can cause discoloration or fading of the veneer. Use curtains, blinds, or UV-protective coatings to minimize sun damage.

By following these simple maintenance practices, you can keep your engineered wood veneer looking as beautiful as the day it was installed.

Considerations When Using Engineered Wood Veneer

While engineered wood veneer offers numerous advantages, there are a few considerations to keep in mind:

1. Refinishing Limitations

The top veneer layer is typically quite thin, which limits the number of times it can be sanded and refinished. In some cases, refinishing may not be possible at all. This makes it important to handle the material with care and avoid excessive wear and tear.

2. Moisture Sensitivity

Although engineered wood veneer is more moisture-resistant than solid wood, it is not completely waterproof. Prolonged exposure to standing water can cause damage, so it’s important to clean up spills promptly and avoid using the material in areas with high humidity or frequent water exposure.

3. Vulnerability to Scratches

The real wood top layer is susceptible to scratches and dents, similar to natural wood. Because of this we will place a tough top coat on top of the engineered wood veneer items we produce.

Why Choose Engineered Wood Veneer?

Engineered wood veneer is a smart alternative to solid wood for many reasons. It offers the timeless beauty of natural hardwood while addressing some of the limitations of solid wood, such as its tendency to warp and crack.

Additionally, its eco-friendly manufacturing process makes it a sustainable choice for environmentally conscious consumers.

Whether you’re designing a modern minimalist kitchen, crafting custom furniture, or renovating an office space, engineered wood veneer provides a versatile, durable, and cost-effective solution.

Its consistent appearance, enhanced stability, and wide range of applications make it a favorite among designers, architects, and homeowners.

Engineered wood veneer is a game-changing material that bridges the gap between aesthetics and functionality. By combining the natural beauty of hardwood with the practical benefits of engineered construction, it has become a go-to choice for a wide range of interior design and construction projects.

Its eco-friendly nature, design consistency, and versatility make it a standout option for anyone looking to achieve the look and feel of solid wood without the associated drawbacks.

As the demand for sustainable and high-quality materials continues to grow, engineered wood veneer is poised to play an even larger role in shaping the future of design and construction. Whether you’re a homeowner, designer, or builder, this innovative material is sure to exceed your expectations and bring your creative visions to life.

At Mondoro we are proud to offer engineered wood veneer and the endless possibilities it brings. We see this as an innovative and fresh approach to natural wood, offering a unique aesthetic and versatility for all kinds of products. It’s not just a material—it’s a new way to reimagine the timeless beauty of natural wood with a modern twist.

Deep Dive Podcast

Check out our Deep Dive Podcast.

Find out more about how Mondoro can help you create, develop, and manufacture excellent home decor and furniture products – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal. You can find it on all major podcast platforms. Try out listening to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel with great videos and information by clicking here.

Related Content

Pantone’s Color of the Year: Cloud Dancer – A Breath of Fresh Air for 2026

In true Pantone fashion, they surprised us all with a choice that goes beyond expectations: Cloud Dancer. This serene, versatile shade has captured my heart, and I believe it perfectly encapsulates the emotions, aspirations, and mindset of 2026.

Read our blog Pantone’s Color of the Year: Cloud Dancer – A Breath of Fresh Air for 2026 by clicking here.

Using Shapr3D and Google Gemini: A Powerful Design Duo

Read on as we will explore how I use Shapr3D, a cutting-edge CAD program, alongside Google Gemini, an AI-powered visualization tool, to enhance my design process. These tools are not just software—they’re design companions that help me bring my creative visions to life in ways that were previously unimaginable.

Read our blog Using Shapr3D and Google Gemini: A Powerful Design Duo by clicking here.

Why AI is the New Design Companion

Design is a deeply personal and creative process, driven by human imagination and ingenuity. At its core, design is about expressing ideas, solving problems, and creating something that resonates with others. But as the world evolves, so do the tools we use to bring our ideas to life. Enter artificial intelligence (AI), a technology that, when used correctly, can become one of the most valuable companions for designers, product developers, and creatives alike.

Read our blog Why AI is the New Design Companion by clicking here.