For many years Mondoro has been producing furniture with rubber wood. I have personally viewed the rubber wood preparation and processing process.

Rubberwood does not contain any latex. Any latex in the wood has already been taken out before the wood is processed as hardwood. Rubber wood is considered eco-friendly as before 1980, the wood was burned as they were not sure how to process the wood properly. New technology allowed rubber wood to be engineered into the beautiful hardwood we know today.

Table of Contents

- Rubber Wood Does Not Contain Latex

- The Process Of Producing Rubber Wood

- Why Rubber Wood Is A Popular Wood Choice?

- Related Content

Rubber Wood Does Not Contain Latex

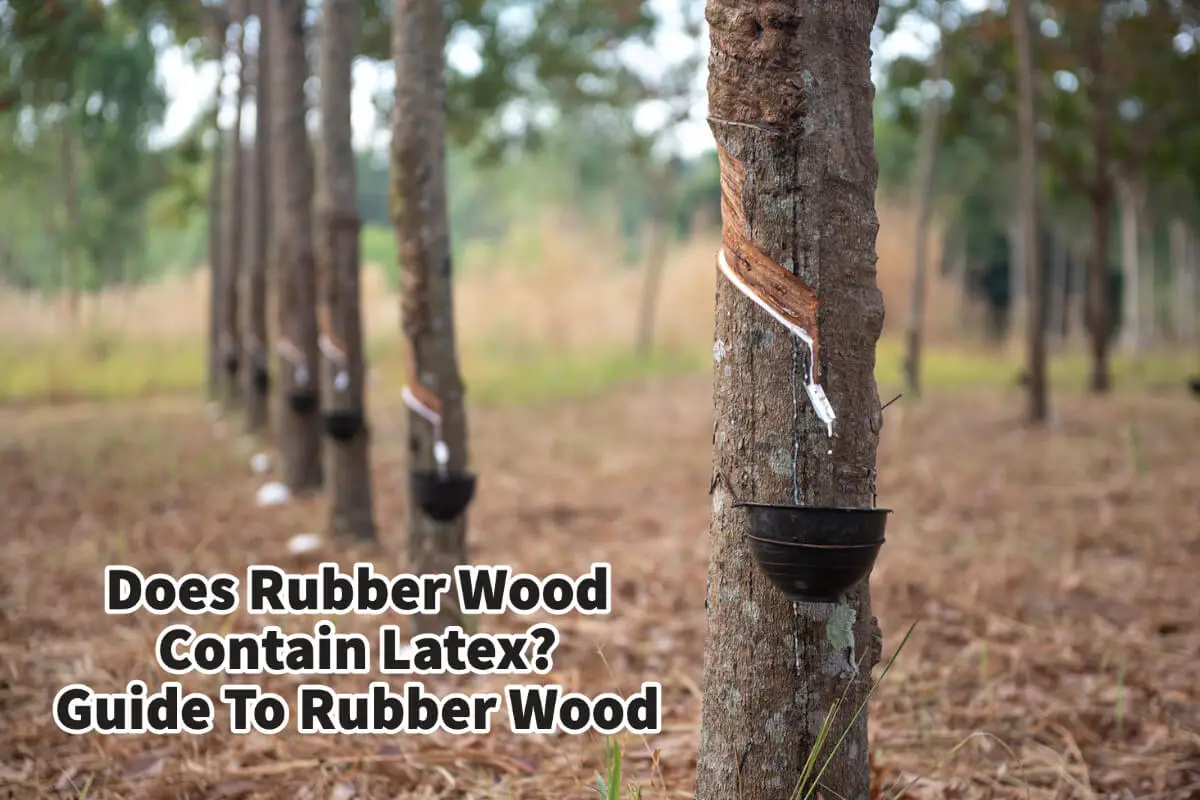

Rubber wood is a hardwood derived from the rubber tree (Hevea brasiliensis) and is primarily grown in Southeast Asia. While the rubber tree does produce latex, rubber wood does not contain any significant amount of latex because the latex is harvested from the tree before the wood is used for lumber.

If you are allergic to latex or have any reactions to latex, you do not need to worry about any rubber wood in your home. I am allergic to latex and have never had any reaction when handling rubber wood; if you are not sure, then talk to a doctor who is an allergy specialist.

The Process Of Producing Rubber Wood

To ensure that rubber wood can be used for furniture and other items, the latex is harvested from the tree when it is about six years old. At this point, the tree has reached maturity and is stopping to produce enough latex regularly.

The latex is collected by making small incisions in the tree’s bark and allowing the sap to flow out. Once the latex has been harvested, and the tree is no longer producing latex, the tree is cut down, and the wood is used for lumber.

Rubber Wood Processing Started In The 1980s

For many years, rubber wood was burned as a waste product because it was not considered a good hardwood. The tree was only used for latex production, and the tree’s wood would go to waste as there was no viable way to use the rubber tree wood.

The problem with rubber wood was that it was prone to warping and cracking, making it challenging to work with and limiting its potential applications.

Hevea Brasiliensis Or Rubber Wood Timber Engineering Explained

However, in the 1980s, a process was developed to make rubber wood more stable and usable as a hardwood. This process is called “Hevea Brasiliensis timber engineering” or “Hevea wood processing.

The process involves several steps, including kiln drying, preservative treatment, and steaming. First, the natural rubber wood logs are cut into lumber and then kiln-dried to remove excess moisture. Next, the lumber is treated with preservatives to protect against insects and fungal decay.

After the preservative treatment, the lumber is placed in a steaming chamber subjected to high-pressure steam. This process softens the wood fibers and makes them more pliable, allowing the wood to be bent and shaped without cracking or splitting.

A factory processing rubber wood must have this steam chamber, or the wood can not be used as a rubber wood hardwood.

Finally, the steamed lumber is kiln-dried again to remove moisture and stabilize the wood’s shape.

Once this process is complete, the rubber wood is transformed into a stable and durable hardwood suitable for various applications, including furniture, flooring, and other decorative items.

Rubber Wood Is Transformed From A Waste Product To Hard Wood

Overall, the Hevea wood processing method has allowed rubber wood to be transformed from a waste product into a valuable and sustainable hardwood that furniture makers and other woodworkers highly prize.

Why Rubber Wood Is A Popular Wood Choice?

Rubber wood is a popular choice for furniture and other items because it is hardwood, which is dense and durable. Unlike some other hardwoods, such as oak or cherry, rubberwood is a sustainable and environmentally friendly option because it comes from a renewable resource.

Additionally, rubber wood is relatively inexpensive, making it a cost-effective option for furniture manufacturers.

Rubber Wood Has A Uniformed Grain Pattern

One of the unique qualities of rubber wood is its uniform grain pattern, which gives it a consistent and attractive appearance. The wood is also easy to work with and takes stains and finishes nicely, allowing it to be customized to match various design styles.

Many factories in Asia prefer rubber wood for furniture as it is stable hardwood and will take well to many finishes. We have used rubber wood for many products and find it an excellent choice for many kinds and types of finishes, looks, colors, and styles.

Rubber Wood Is Eco-Friendly

The added benefit of rubber wood is that you can say it is an eco-friendly wood that once would have been burned before the process of using the wood was invented.

Even though the rubber tree does produce latex, rubber wood does not contain any significant amount of latex because the latex is harvested before the wood is used for lumber. This makes rubberwood a sustainable, cost-effective hardwood with a consistent and attractive appearance, making it a popular choice for furniture and other items.

If you are interested in seeing how Mondoro can be a valuable partner for you for wood furniture products – we would love to talk to you to see how we can help you.

Find out more about how Mondoro can help you create, develop, and manufacture excellent home decor and furniture products – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal. You can find it on all major podcast platforms. Try out listening to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel with great videos and information by clicking here.

Related Content

Hardwood Solids Furniture, What Does The Term Mean?

Hardwood solids can include non-solid woods such as engineered woods. Hardwood solids are used in furniture and other industries to classify what wood is used in a product. The terms usually do not classify what type of wood is used.

You can discover more by reading Hardwood Solids Furniture, What Does The Term Mean? by clicking here.

Differences Between Solid Wood, Plywood, Pressboard, And OSB?

Solid wood is wood cut from a tree and made into products; plywood is considered engineered wood. Pressboard is made from paper, including recycled paper. OSB is also known as Oriented Strand Board, and because of its strength is used a lot in roofing, housing, and floors.

You can discover more by reading our blog Differences Between Solid Wood, Plywood, Pressboard, And OSB? by clicking here.

What Is Solid Wood Vs. Engineered Wood?

Solid wood is cut down from the tree, cut into wood boards, and used for manufacturing. On the other hand, engineered wood is considered manmade as it is usually manufactured with wood chips, wood shavings, and an adhesive. Today the manufacturing of engineered wood is highly technical.

You can discover more by reading our blog All About Teak Wood And Outdod? by clicking here.