Anyone looking to ship a container by sea must check if the container they receive is seaworthy. If the container they load on a ship is not seaworthy, your goods can be damaged en route.

No matter what products you are shipping, there are four basic ways to check that a container is seaworthy. One is to check the container when you pick it up. The other is to check the container carefully and look at the seven major parts of the container. We recommend that you always take many photos of both the empty container before you load it and the container as you are loading it.

Table of Contents

- 4 Essential Steps to Ensure Your Shipping Container is Seaworthy

- Frequently Asked Questions

- Related Content

4 Essential Steps to Ensure Your Shipping Container is Seaworthy

Ensuring that a shipping container is seaworthy is crucial for anyone planning to transport goods across the ocean. The container’s integrity is fundamental to the cargo’s safety and security. A container that fails to meet seaworthy standards can significantly damage the goods during transit.

When verifying the seaworthiness of a shipping container, there are four primary methods to employ. The first involves a thorough inspection of the container at the time of pick-up.

Additionally, a detailed examination of the container’s seven key components is vital to assess its condition. It is also highly advisable to document the container’s state through extensive photographic evidence, both when it is empty and during the loading process. This approach ensures the safety of your goods and provides valuable documentation in case of any disputes or insurance claims.

One of the primary reasons you want to check that your containers are seaworthy is that if the cargo container has holes, your products can get wet, and water can get into the container and cause water damage. Cargo containers that are not sealed against water damage can usually get water in them.

Check Container Is Seaworthy At Pick Up

If you or one of your employees is going to pick up the container from the port directly, then one of the easiest things you can do is check that the container’s port is considered seaworthy. But most people, ourselves included, will use a company to help pick up the container; you can instruct the company to check the cargo container is seaworthy.

If you can check the container’s seaworthiness at the port, it will save you a lot of problems as then you can:

- Request A New Container – If you see the container is not seaworthy, you can request to change the container and inform the shipping company that the container is not seaworthy.

- Will Save Costs – It will save you by not having to return the container to get a new one.

- Save Time – If the container is not seaworthy and must go back to the port, it will also save you time; in some instances, the shipping time may be short, so you may not make your shipment date if you must return the container for a new container.

That is why it is best always to look to check the container at the port. If you have a company picking up the container for you, you can clearly instruct them only to pick up seaworthy containers and give them the list below of the seven essential points that should be checked for a container.

7 Point Of Checking Container Is Seaworthy

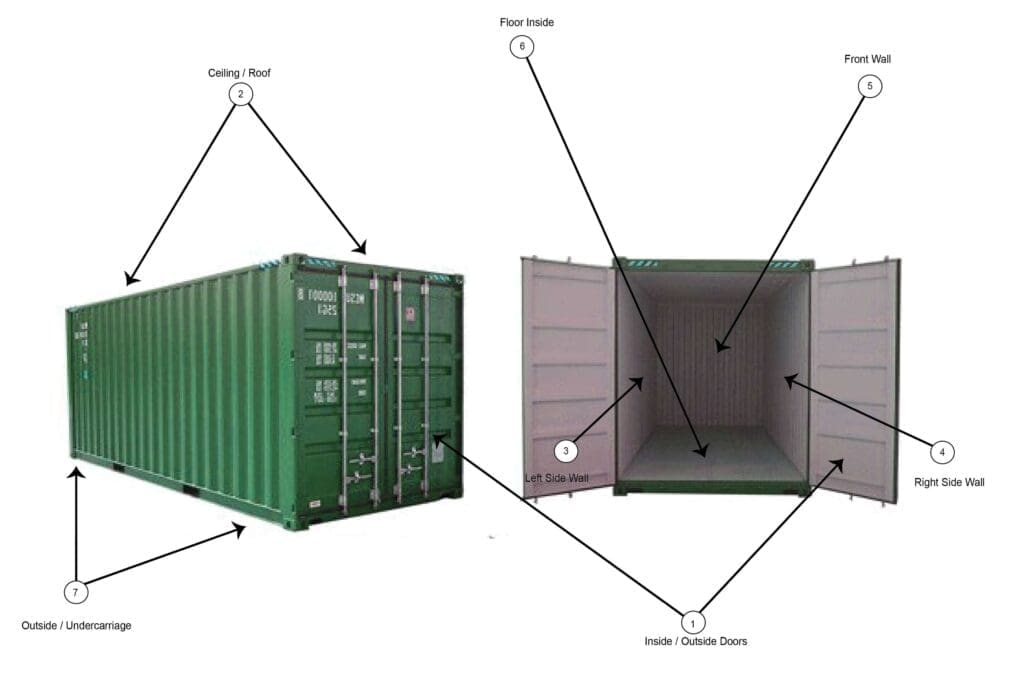

For any container you pick up for the boatyard, there are seven major points that you should check to ensure the container is seaworthy.

One of the best ways to check this is to get into the container, close the door, and see if you see any light; if light shines through, the container has a hole.

Seven Areas to Check for Seaworthiness:

- Inside and Outside Doors – Check the inside and outside doors. Make sure the doors will lock correctly, and there are no significant gaps in the door where water can get into the container.

- Ceiling and Roof – Check that the ceiling and roof are defect-free.

- Left Side Wall – Check that the left side wall is free from any significant defects.

- Right Side Wall – Check the right side wall is free from any significant defects.

- Back Wall – Check that the back wall is also free from defects.

- Floor Inside – Carefully check that the floor inside the container is free from defects and can hold all the goods. If the floor is heavily rusted, this can be a problem.

- Outside and Undercarriage – Look outside the container, particularly at the undercarriage.

If you check all these areas, it will help you to ensure the container is seaworthy.

Take Photos Of The Empty Container

Take many photos of the empty container to show that the container has been checked. If you find the container is defective, then the photos will also help you to work with the shipping company to return the container.

Taking a photo is an essential step as it will help you to ensure that you have evidence to show that the container was checked and in what condition the container left your destination. Sometimes a container may leave you in good condition, but by the time it arrives, there can be issues. The photos will help with any insurance claims that need to be filed.

Take Photos Of The Container Loading

Always take photos of the container loading. This will help protect you if there is a complaint when the goods arrive at the destination.

The photos help to give a photographic record of what and how the goods were loaded onto the container. As photos today are easy and cheap to take, we recommend that you take a lot of photos and then save them for at least 18 months after the shipment so that you have a record of how the container was loaded.

Sometimes, goods can shift during the handling and shipment of a container, so if there is an issue at the destination, you will have photos to show how the container was packed before shipment.

Following these basic four steps should help ensure that any containers you ship will be seaworthy and the products you ship will arrive at their destination safely.

Find out more about how Mondoro can help you create, develop, and manufacture excellent home decor and furniture products – don’t hesitate to contact me, Anita. Check out my email by clicking here or become a part of our community and join our newsletter by clicking here.

Mondoro gives out a FREE Lookbook to anyone interested. You can receive a copy of our latest Lookbook by clicking here.

Listen to our Podcast called Global Trade Gal. You can find it on all major podcast platforms. Try out listening to one of our podcasts by clicking here.

Subscribe to our Mondoro Company Limited YouTube Channel filled with great videos and information by clicking here.

Frequently Asked Questions

Why is it important to check if a container is seaworthy before shipment?

Ensuring that a container is seaworthy is crucial to prevent potential damage to goods during transit. Containers that are not seaworthy may be prone to leaks, structural issues, or other problems that can compromise cargo safety.

When should I check the container for seaworthiness?

It is recommended to check the container at two key stages: when picking it up and during the loading process. Regular inspections help identify any issues early on and allow for corrective actions to be taken.

What are the four basic ways to check if a container is seaworthy?

The four basic ways include inspecting the container during pickup, carefully examining its seven major parts, and taking multiple photos of the empty container before loading and during the loading process.

What are the seven major parts of a container that should be examined for seaworthiness?

The seven major parts to check include the roof, floor, doors, corner castings, cross members, side panels, and the understructure. Examining these components helps ensure the overall integrity of the container.

How does the clipping mask function in Procreate contribute to product design?

While the clipping mask function in Procreate is not directly related to container seaworthiness, it is a useful tool for product designers, particularly in home decor and furniture design. It helps create precise and intricate designs by restricting the visibility of elements outside a defined shape.

Why is it recommended to take photos of the container during the inspection process?

Taking photos of both the empty container and the loading process provides visual documentation. This documentation can be useful for dispute resolution, insurance claims, and as evidence in case any issues arise during shipment.

Can containers be made seaworthy after identifying issues during the inspection?

Yes, in many cases, identified issues can be addressed and corrected before shipment. However, it’s essential to communicate any problems with the shipping company and ensure that necessary repairs or modifications are made to make the container seaworthy.

What are the common problems that can make a container not seaworthy?

Common problems include rust, leaks, structural damage, faulty doors, and issues with the corner castings. Any defects in these areas can compromise the container’s ability to withstand the challenges of sea transport.

Are there specific regulations or standards for container seaworthiness?

Yes, international organizations such as the International Maritime Organization (IMO) and industry standards like the Container Safety Convention (CSC) have established regulations and guidelines for container seaworthiness. Compliance with these standards is essential.

Is there a checklist available for container seaworthiness inspections?

Yes, many shipping companies and organizations provide checklists for container inspections. It’s recommended to use these checklists to ensure a comprehensive examination, covering all critical aspects of container seaworthiness.

Related Content

10 Tips On Loading A Dry Shipping Container, What You Need To Know

A dry shipping container is a container that is used for 90% of all worldwide shipments. The dry shipping containers’ standard sizes are 20’, 40’, and 40’ HC container sizes. Each size has different payload weights and loading size limits, so when you prepare to load your container, the container size you choose will make a huge difference in the actual container loading.

You can learn more by reading 10 Tips On Loading A Dry Shipping Container, What You Need To Know by clicking here.

What Is The DUPRO Or During Production Inspection?

The DUPRO Inspection is a product inspection conducted during the manufacturing phase of production. The DUPRO is also known as during the production inspection, as its main purpose is to find any errors during the product’s manufacturing phase. Most manufacturing errors are easier to fix during the production process instead of when the goods are completed.

You can find out more about DUPRO by reading our blog DUPRO, During the Production Product Inspection Guide by clicking here.

How Do I Find An Overseas Manufacturer To Produce My Product Ideas?

For many people, the biggest hurdle they have in importing products from overseas is finding the right overseas supplier to produce their products. To find a reliable overseas manufacturer to produce your product ideas, there are some basic steps you can take 1) Find a reliable trade agent to help you find manufacturers, 2) attend trade shows in your industry, 3) research online to find a supplier 4) talk to trade organization and 5) try to get a referral from someone in your industry.

You can find out more about how to find a manufacturer to produce your products by reading our blog How Do I Find An Overseas Manufacturer To Produce My Product Ideas? by clicking here.